| Features |

Starter

€ 59.00

/ month

billed annually |

Advanced

€ 199.00

/ month

billed annually |

Professional

€ 299.00

/ month

billed annually |

Professional 3D

€ 499.00

/ month

billed annually |

|---|---|---|---|---|

Features |

||||

|

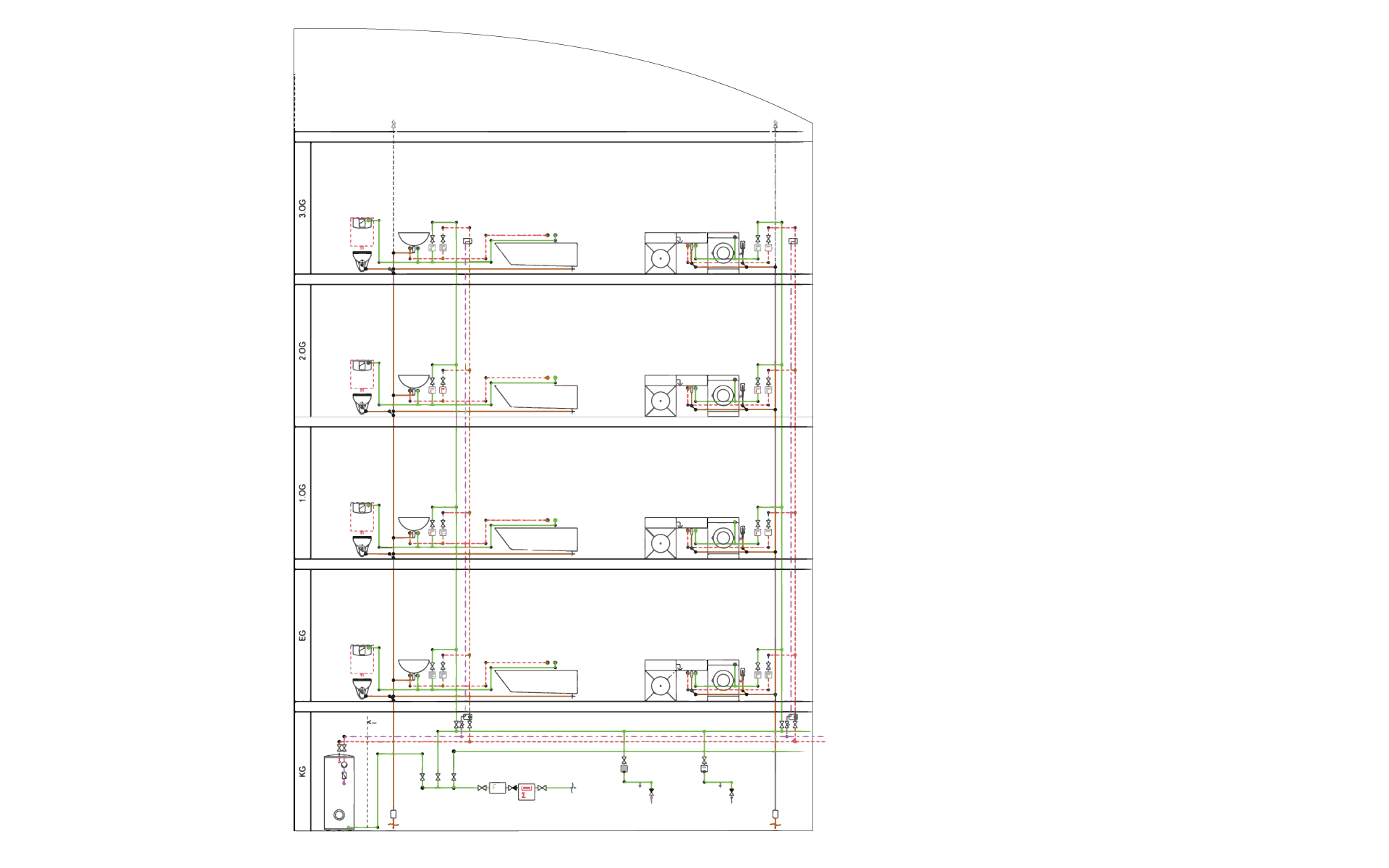

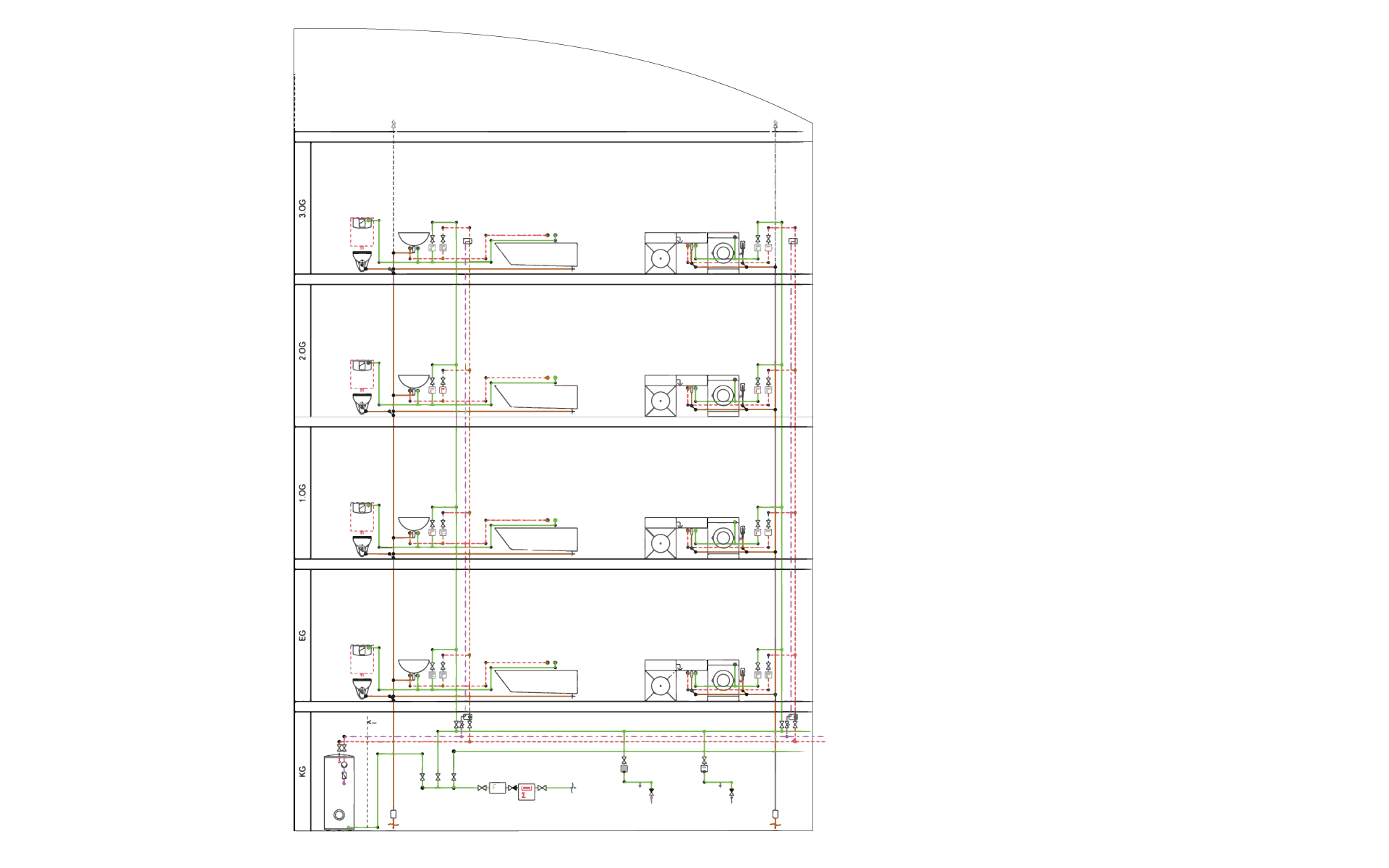

MEP Model Creation (Heating, Cooling & Gas) For example:

|

Yes | Yes | Yes | Yes |

|

Scheme generator (Heating + Gas) Create the fastes schemes in the industry with the powerfull scheme generator For example:

|

Yes | Yes | Yes | Yes |

|

Storey table For example:

|

Yes | Yes | Yes | Yes |

|

Visibility Control For example:

|

Yes | Yes | Yes | Yes |

|

Industry Components via CAD Browser For example:

|

Yes | Yes | Yes | Yes |

|

Creation and Preperation of the Architectural Model for Calculations For example:

|

Yes | Yes | Yes | Yes |

|

Building Analysis For example:

|

No | Yes | Yes | Yes |

|

Heat Load Calculation For example:

|

No | Yes | Yes | Yes |

|

Dimensioning of Radiators & Convectors For example:

|

No | Yes | Yes | Yes |

|

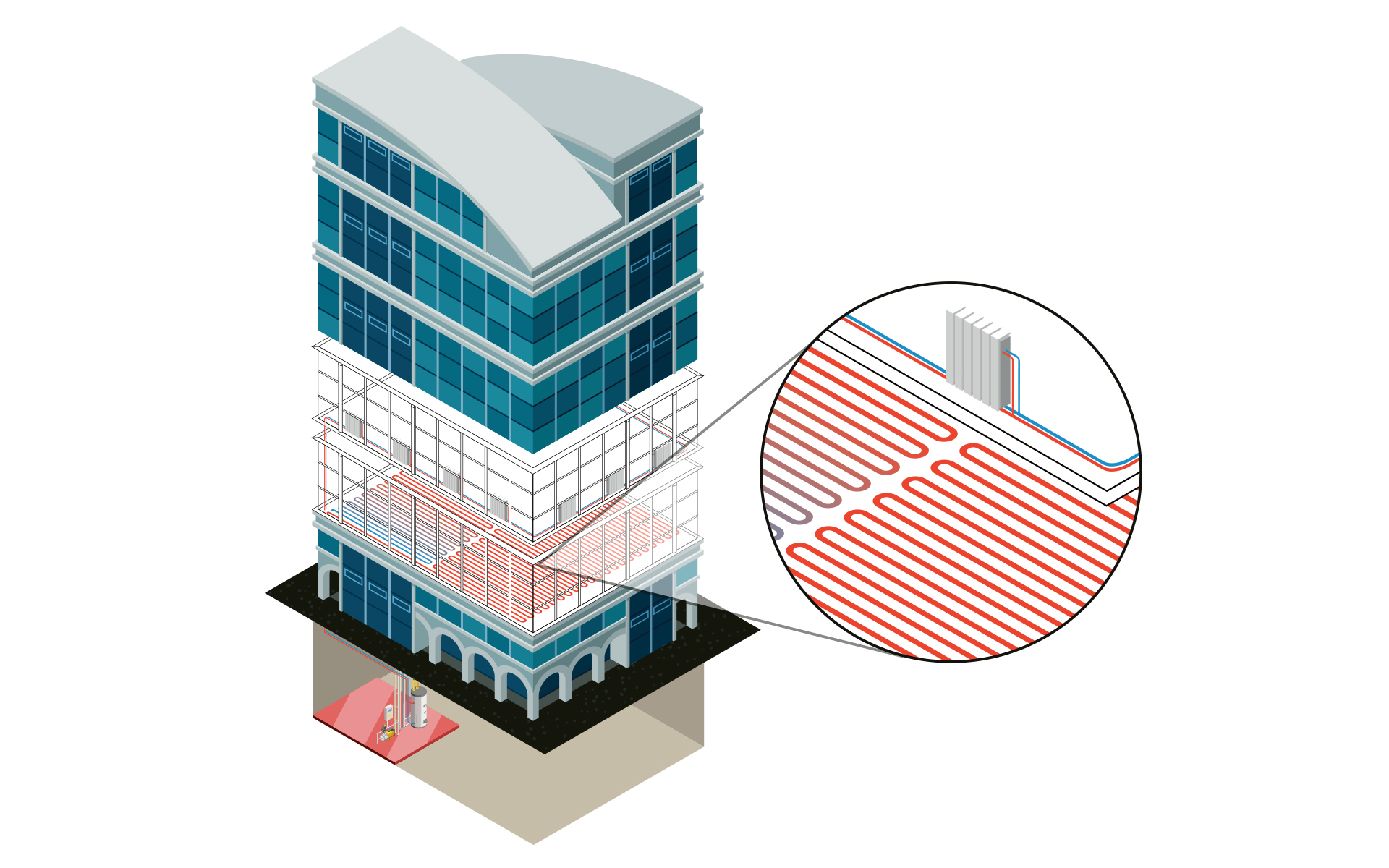

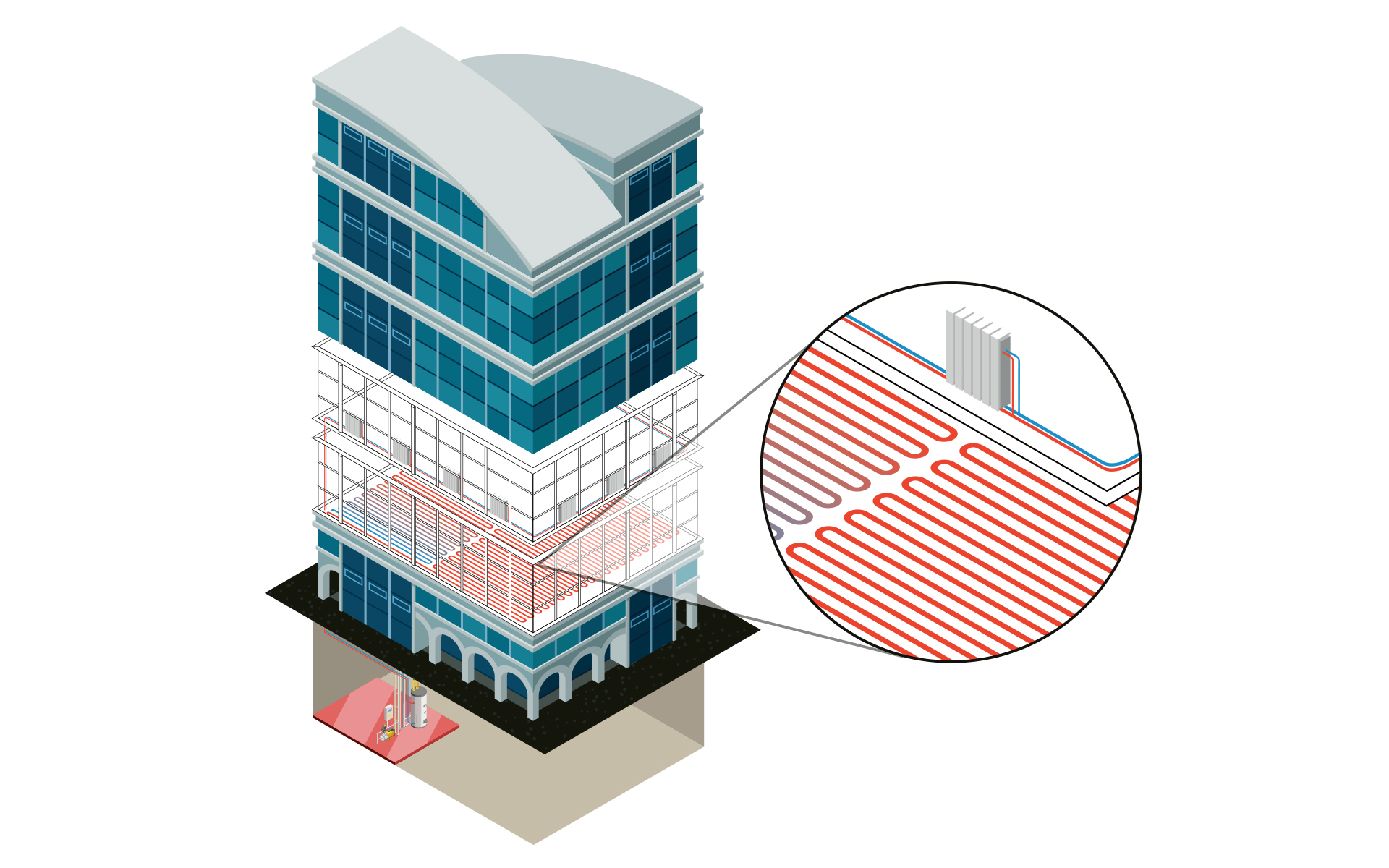

Dimensioning of Panel Heating For example:

|

No | Yes | Yes | Yes |

|

Automatic Drawing of dimensioned Components For example:

|

No | Yes | Yes | Yes |

|

Automatic Detection of the Heating Pipe Network For example:

|

No | No | Yes | Yes |

|

Heating Pipe Network Calculation with Redimensioning For example:

|

No | No | Yes | Yes |

|

Hydraulic Balancing of complex Systems For example:

|

No | No | Yes | Yes |

|

Bill of Quantities including Article Numbers For example:

|

No | No | Yes | Yes |

|

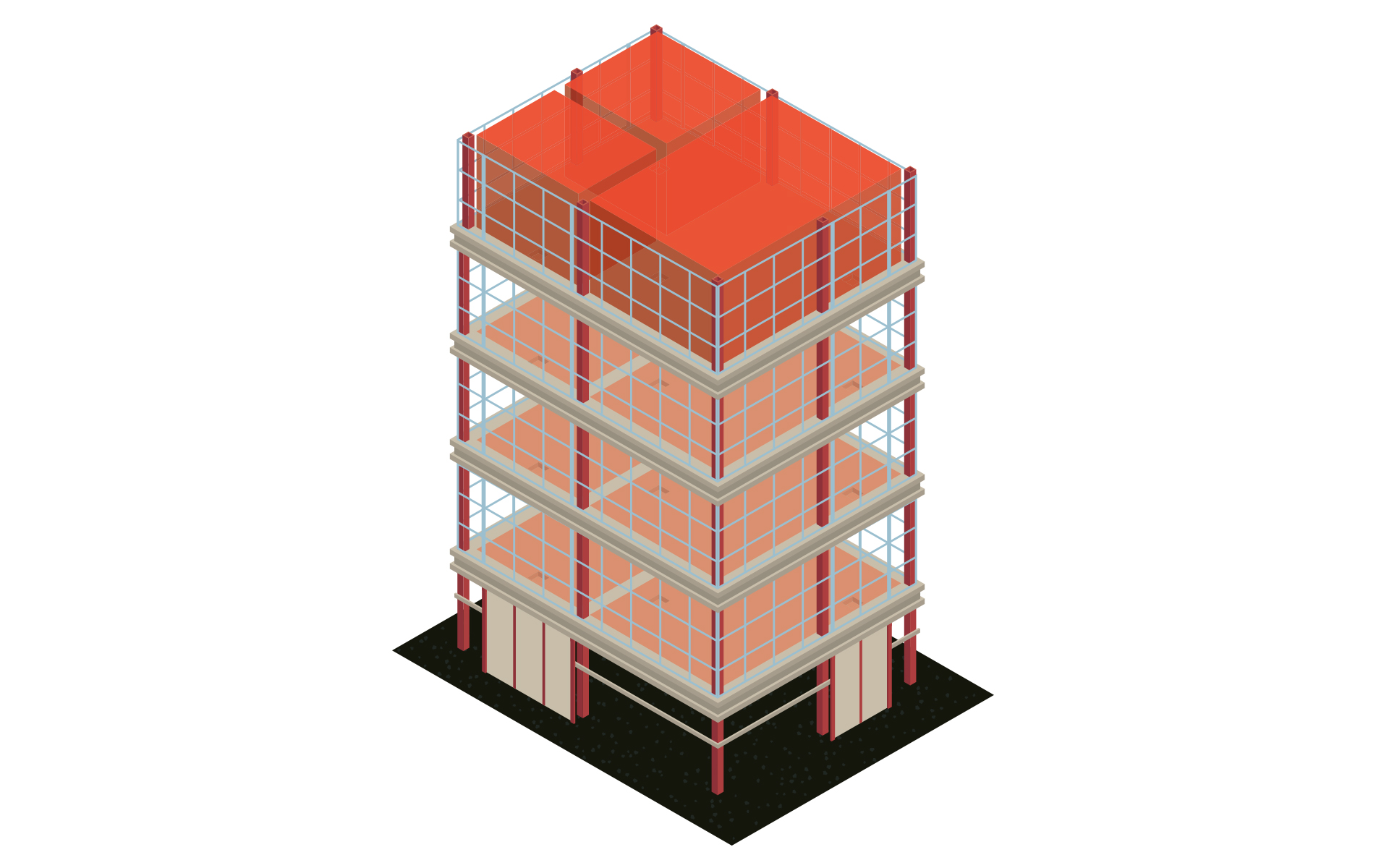

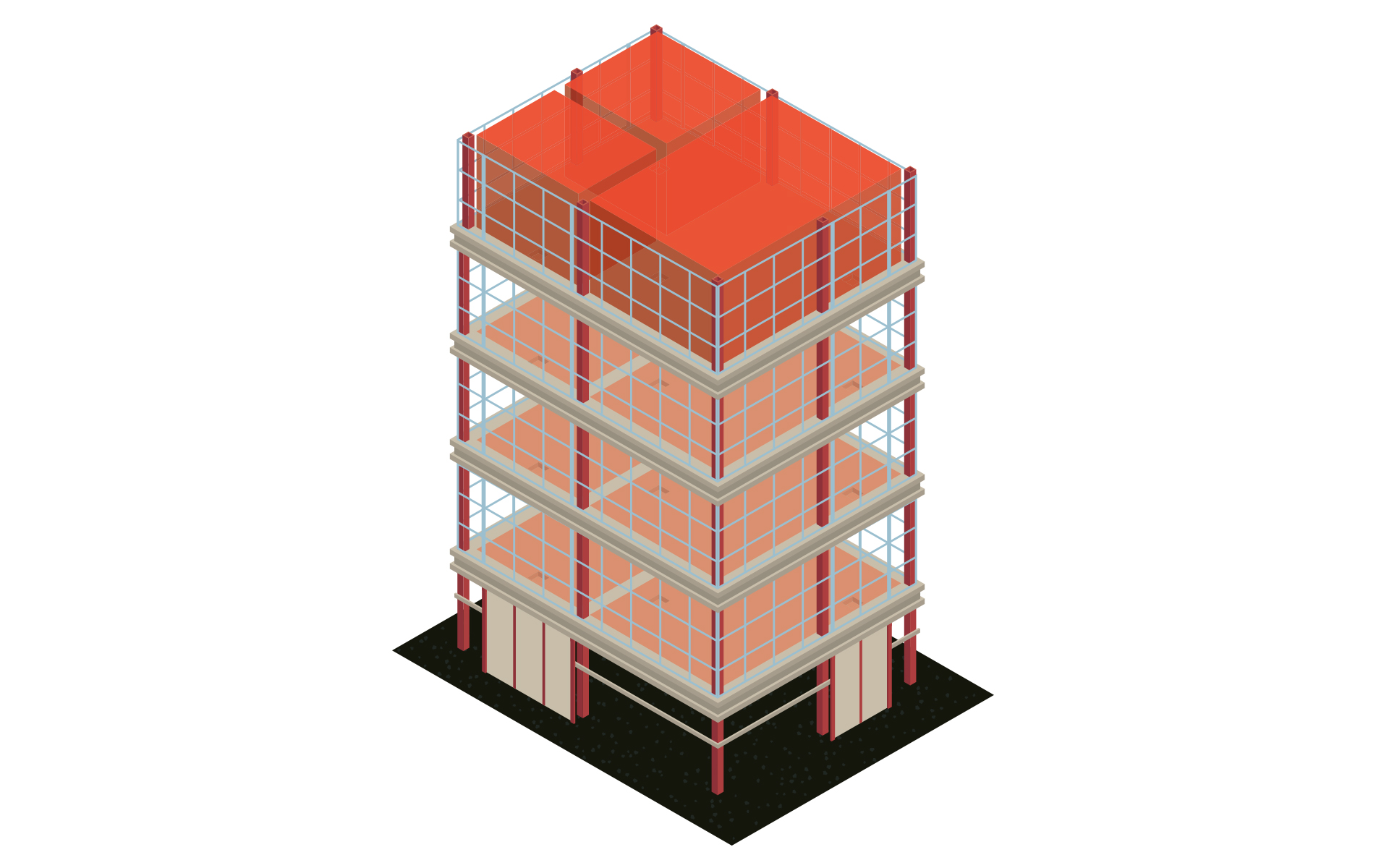

Detailed 3D Design (Heating, Cooling, Gas, Potable Water, Waste Water) For example:

|

No | No | No | Yes |

|

Free Access to Online Tutorials

|

Yes | Yes | Yes | Yes |

Heating Solutions for AutoCAD

Editions

Videos

Description

LINEAR workflow for heating design with Autodesk AutoCAD

Schematic design

Input: Supply requirements for the building

Output: Calculable scheme design

Work steps:

- Create storey table

- Manual scheme creation with toolbars and specific editing commands

- Scheme generator for drag and drop and automated drawing

Derivation of the thermal model

Input: Architecture plan

Output:Model for further MEP design including levels and rooms

Work steps:

- Referencing DWGs, DXFs or PDFs from the architect

- Create storey table

- Create and enrich the architecture with room data

Building analysis and heating load calculation

Input: Architecture model with additional information for analysis

Output: Calculated heat load

Work steps:

- Powerful building analysis as a basis for the heat load calculation

- Automatic mapping of the building structure (building parts, storeys and rooms)

- Identification and collaborative correction of modeling errors in exchange with the architect

- U-value calculation and addition of any missing calculation parameters

- Automatic heat load calculation for the project, the storeys as well as all rooms

- Transfer of all relevant values into the model

Radiator and panel heating dimensioning

Input: Calculated heat load

Output: MEP model with dimensioned heating components

Work steps:

- Dimensioning of radiators, convectors or panel heating systems on the basis of the heat load calculation

- Comparison of variants by using verified manufacturer data sets

- Transfer of the designed components into the model

- Optional automatic or manual placement of components

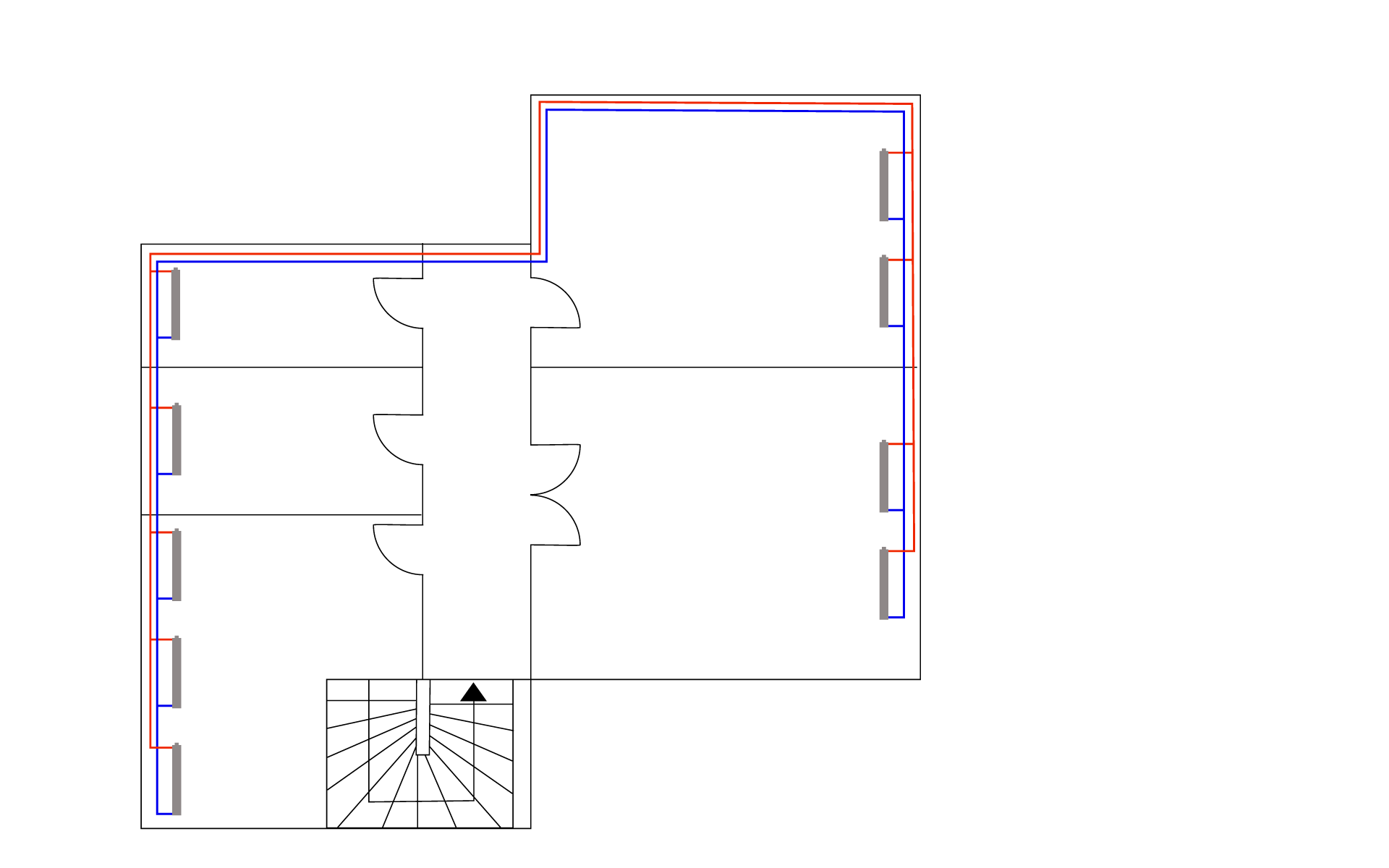

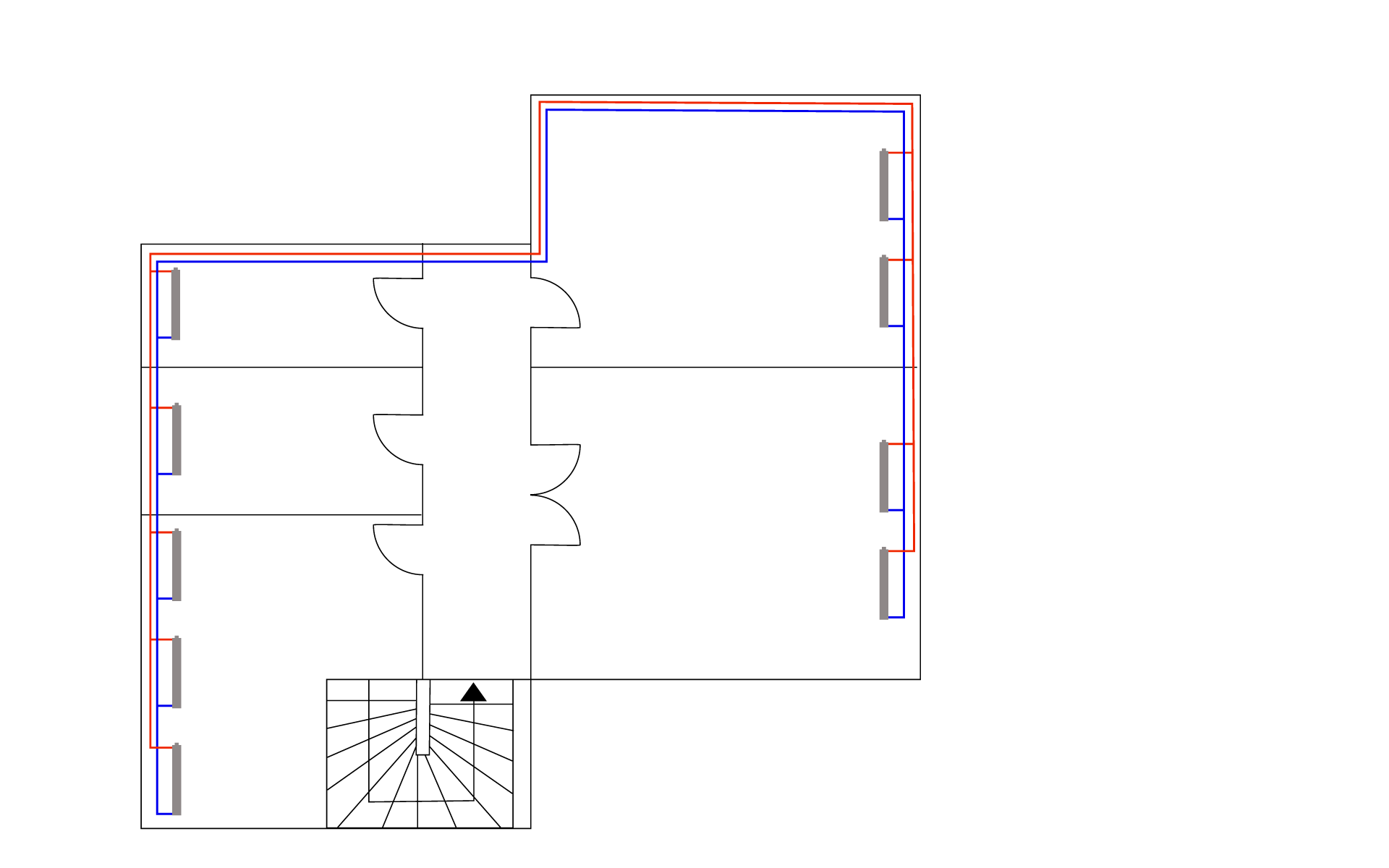

Create system in the isometry or floor plan

Input: MEP model with dimensioned heating components

Output:MEP Model with a calculable network (isometric or floor plan)

Work steps:

- 2D or isometric pipe network design using time-saving construction commands

- Automatic connection of all consumers

- System design in a neutral way or with the help of extensive manufacturer CAD libraries

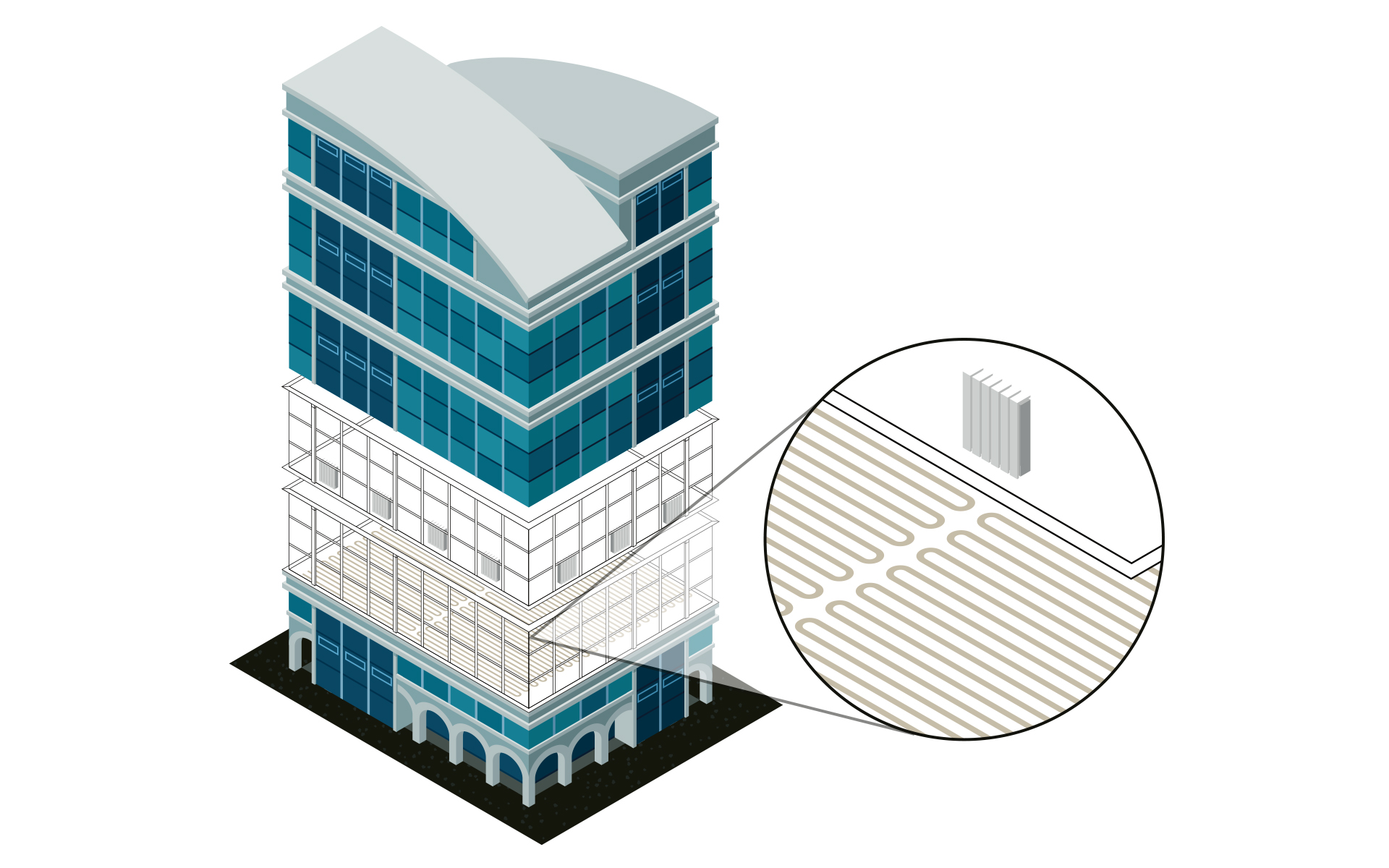

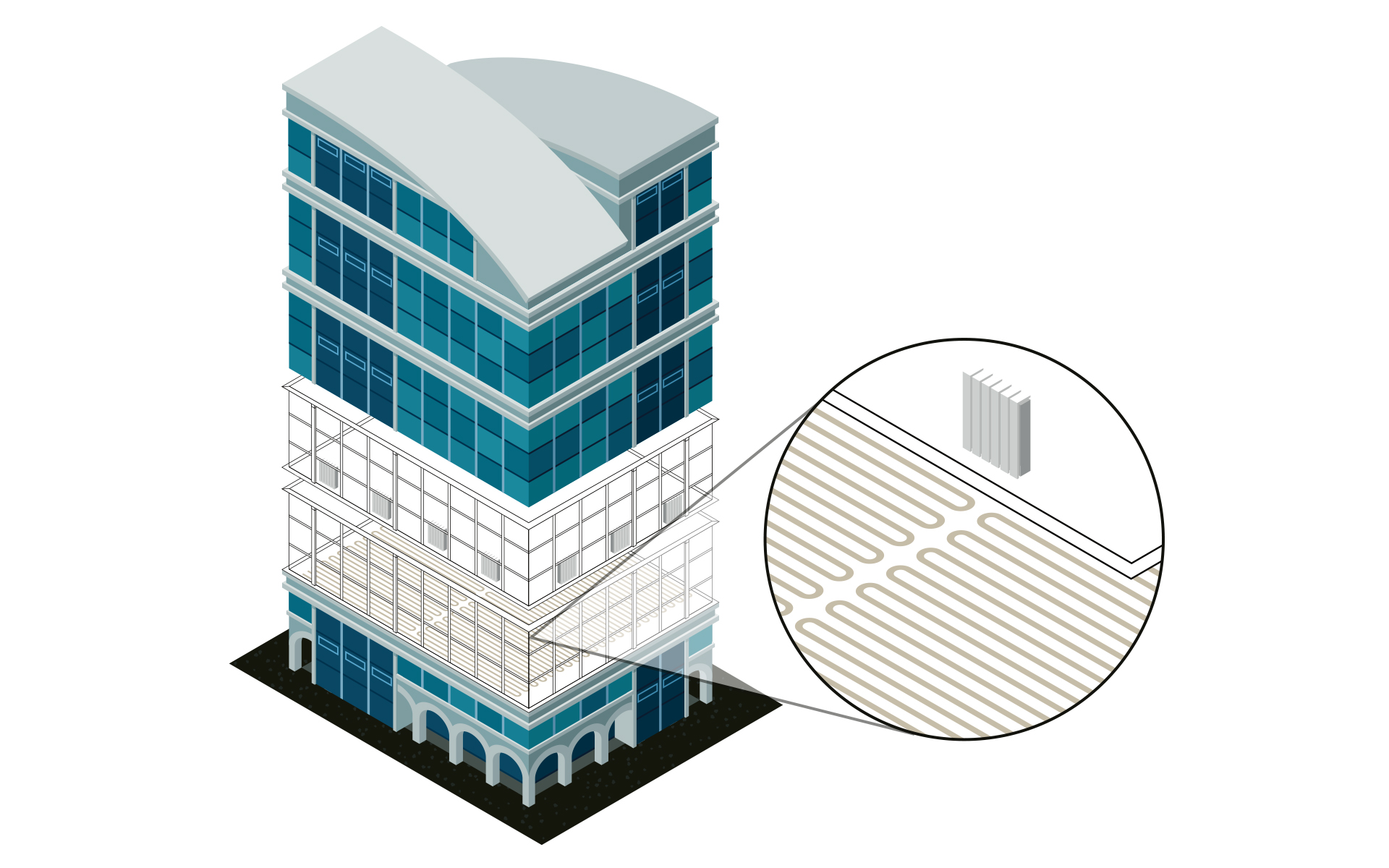

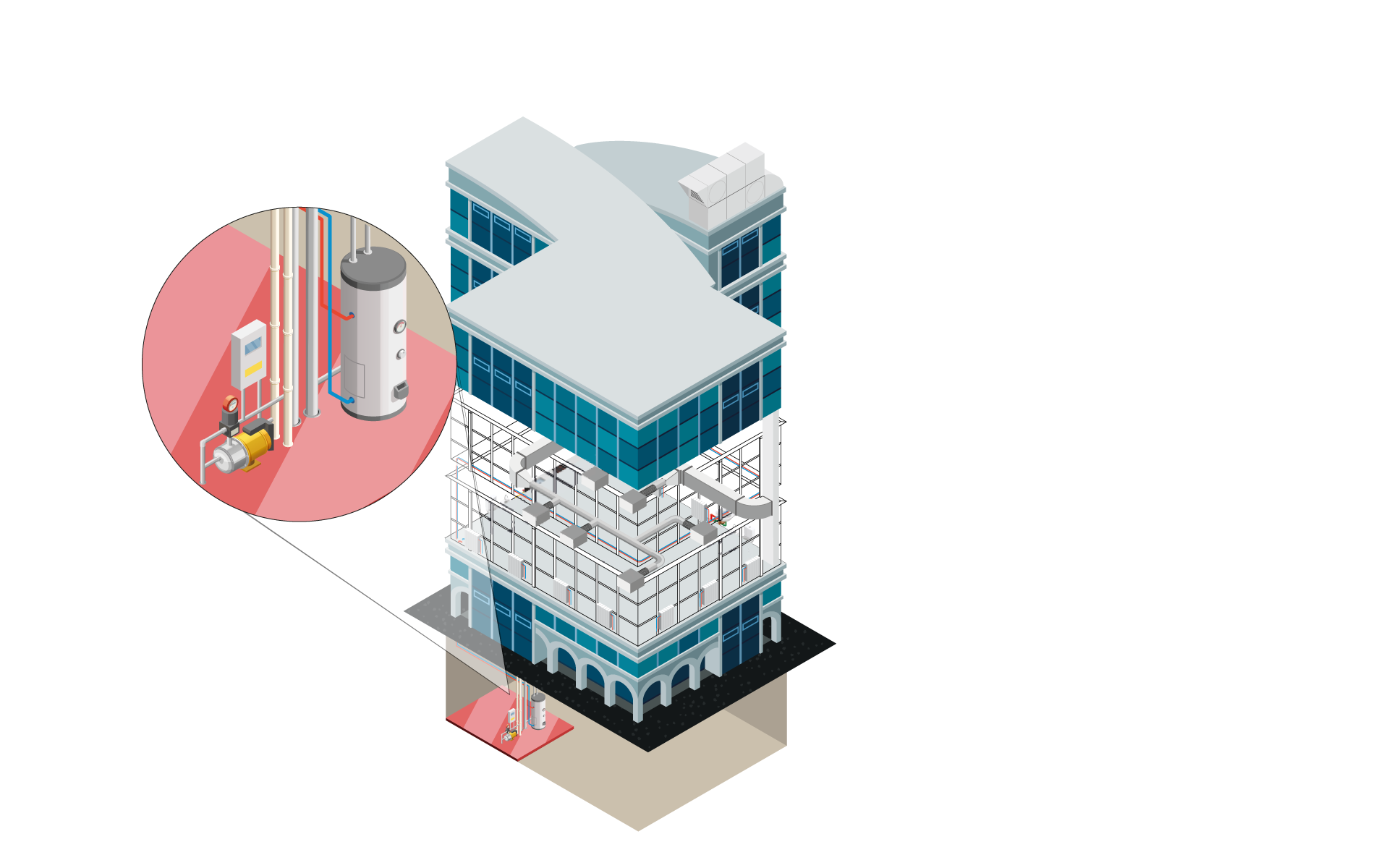

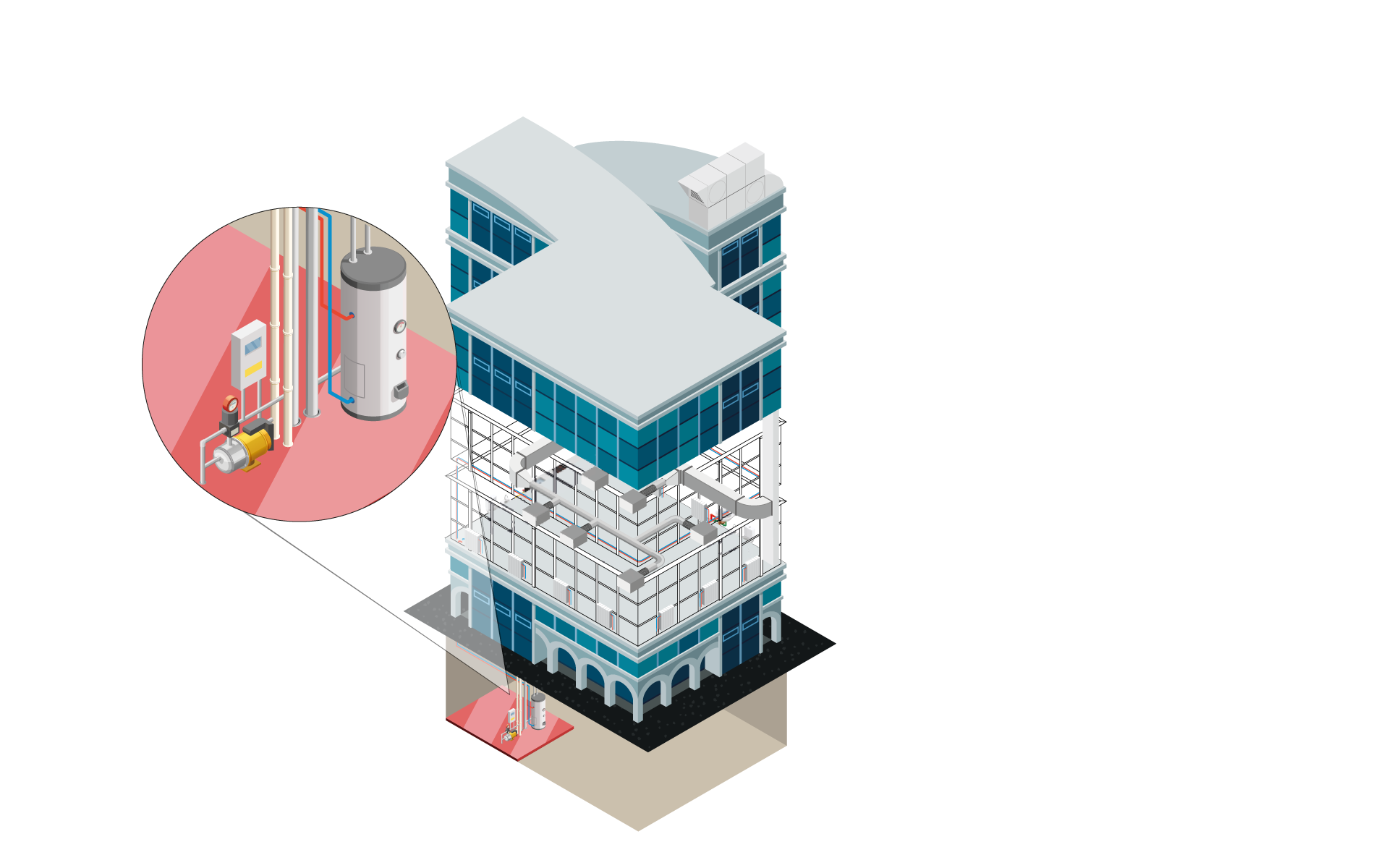

Create system in 3D

Input: MEP model with dimensioned heating components

Output: Detailed 3D model

Work steps:

- Detailed pipe design

- Automatic routing functions with preview of possible alternatives

- System design in a neutral way or with the help of extensive manufacturer CAD libraries

- Subsequent placement of components with matching transitions and flanges

- Automatic bolting of the entire construction (bolts, nuts, washers) with complete transfer to the parts list

- Pre-define insulation materials and show/hide them with transfer to the parts list

- Real-time collision check

- Manually or automatically assigned item numbers

- Material lists, parts lists with article numbers, sawing lists for pipes, position lists

Heating pipe network calculation

Input: Schematic, 2D or 3D model

Output: MEP model with optimized heating system (schematic, 2D or 3D)

Work steps:

- Specification of calculation-relevant specifications (e.g. assignment of pipe materials, settings of valves, specification of insulation and ambient temperatures).

- Comparison of variants by using verified manufacturer data sets (e.g. pipe systems)

- Calculation of existing networks by fixing individual or all dimensions

- Redimensioning of the heating pipe network based on the calculation

- Colored display of all results directly in the model

- Automatic 3D generation during system creation in 1-stroke (step 5 - variant 1)

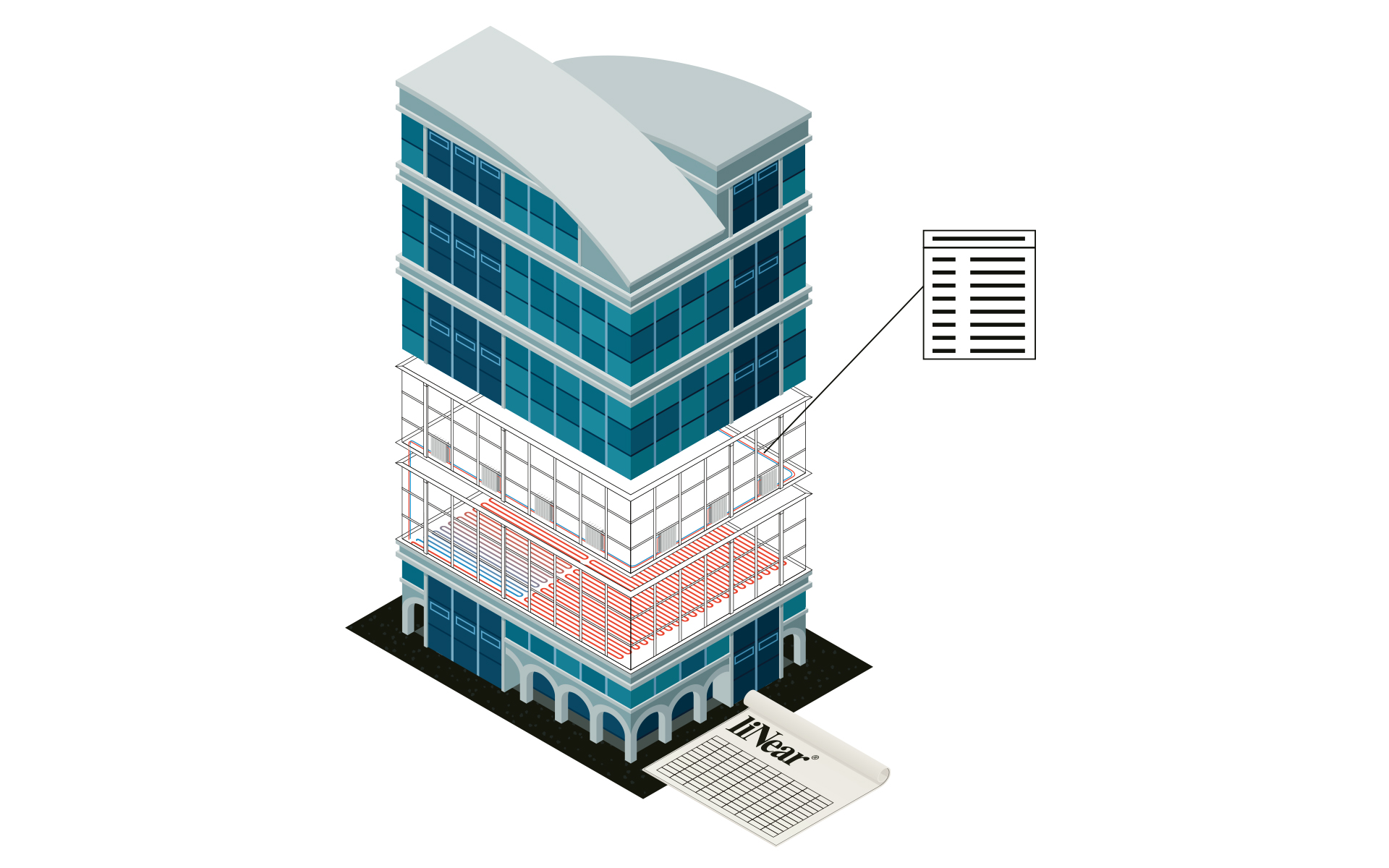

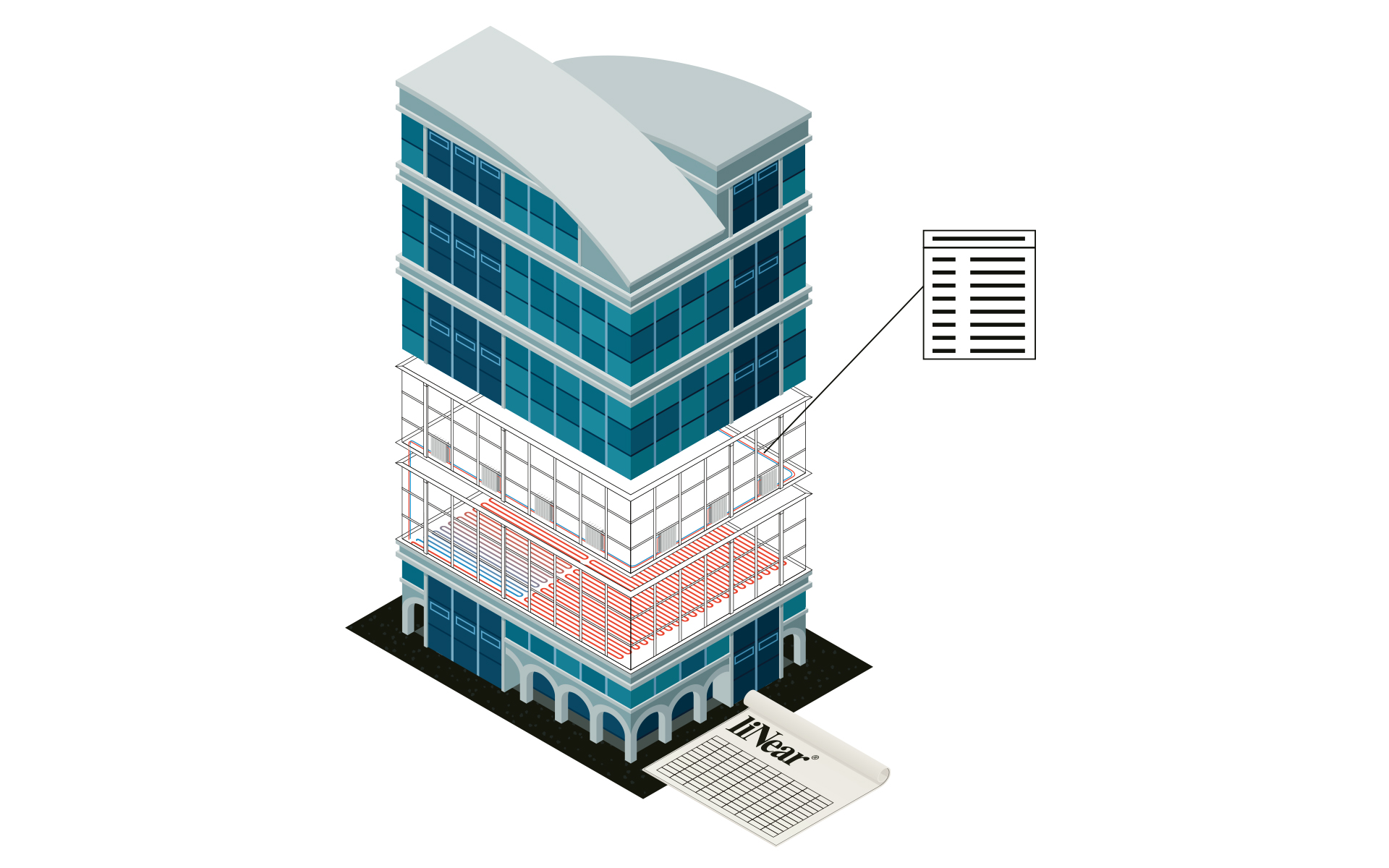

Labeling, output of model data and results

Input: Calculated and optimized heating pipe network

Output: Final heating design including model for transfer to the coordination model and calculated results incl. material lists

Work steps:

- Saving of all inputs and calculation results in the model

- Publication of selectable values as component data

- Automatic labeling of the model

- Addition of own parameters and meta information

- Printout of the results in standardized forms

- Transfer of results and model in all relevant formats