| Features |

Starter

€ 59.00

/ month

billed annually |

Professional

€ 249.00

/ month

billed annually |

Professional 3D

€ 399.00

/ month

billed annually |

|---|---|---|---|

Features |

|||

|

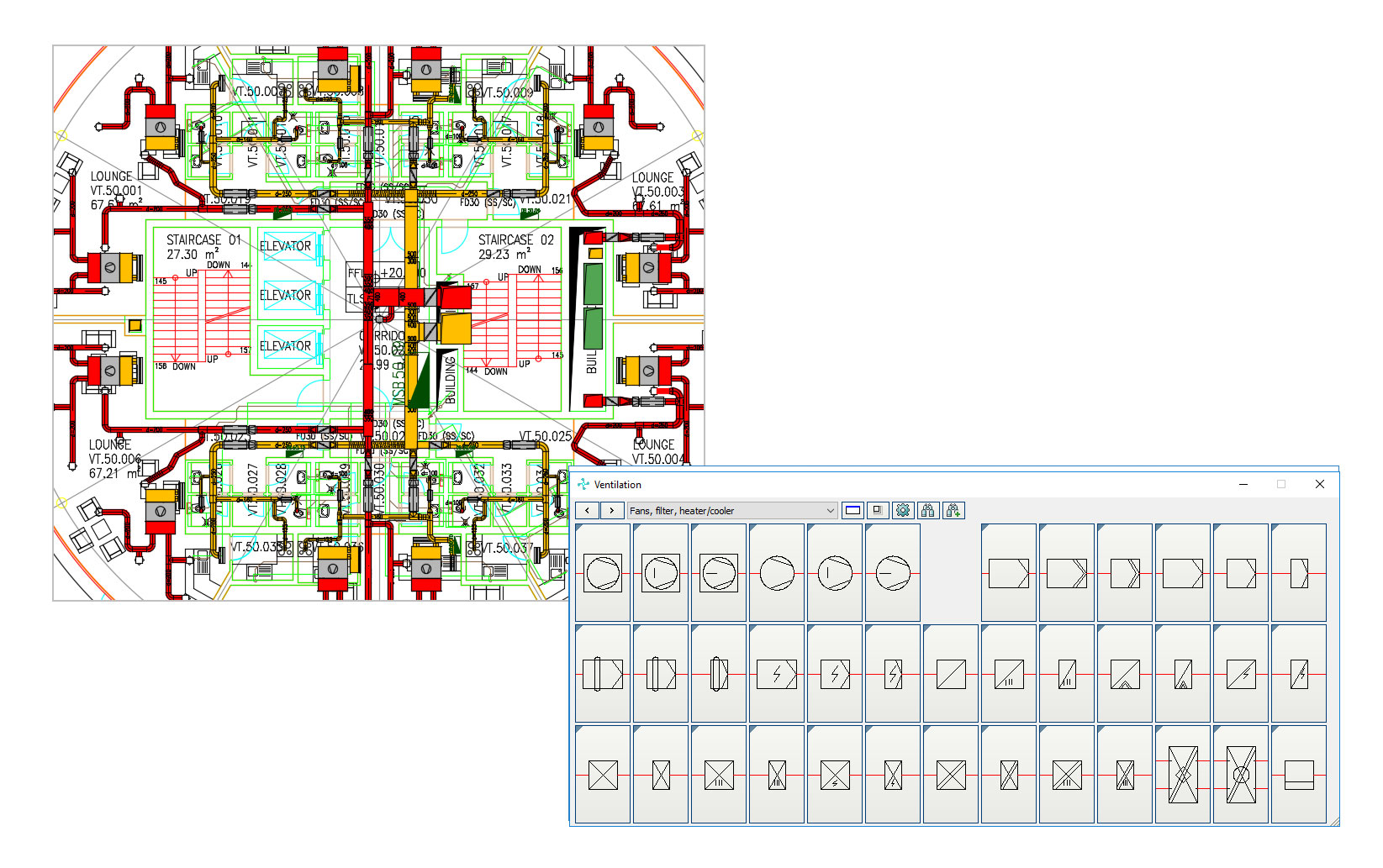

MEP Model Creation (Ventilation) For example:

|

Yes | Yes | Yes |

|

Storey table For example:

|

Yes | Yes | Yes |

|

Visibility Control For example:

|

Yes | Yes | Yes |

|

Industry Components via CAD Browser For example:

|

Yes | Yes | Yes |

|

Automatic Detection of the Air Duct Network For example:

|

No | Yes | Yes |

|

Air Duct Network Calculation with Redimensioning For example:

|

No | Yes | Yes |

|

Flow mechanical Balancing of complex Systems including Sound Level Calculation For example:

|

No | Yes | Yes |

|

Bill of Quantities including Article Numbers For example:

|

No | Yes | Yes |

|

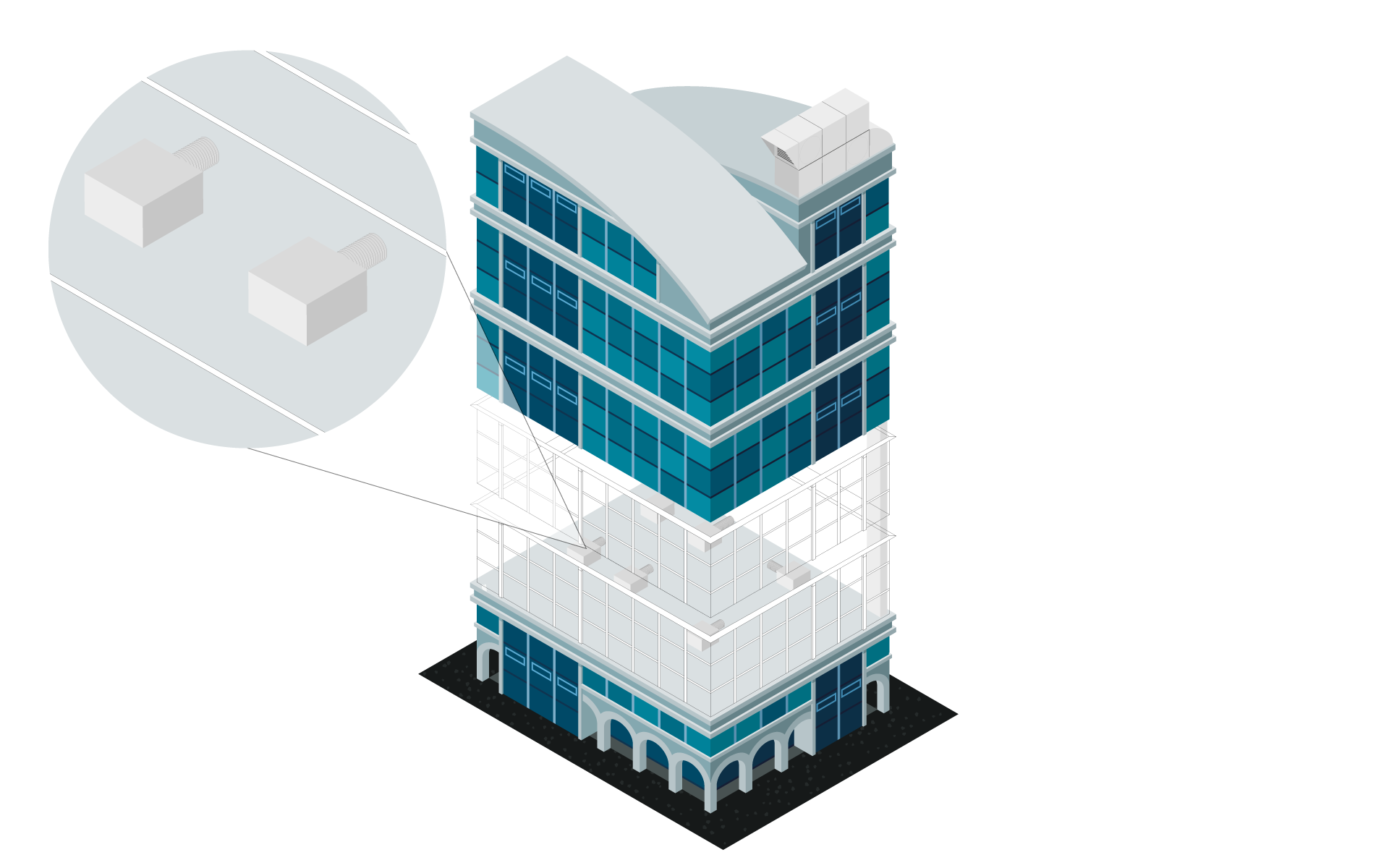

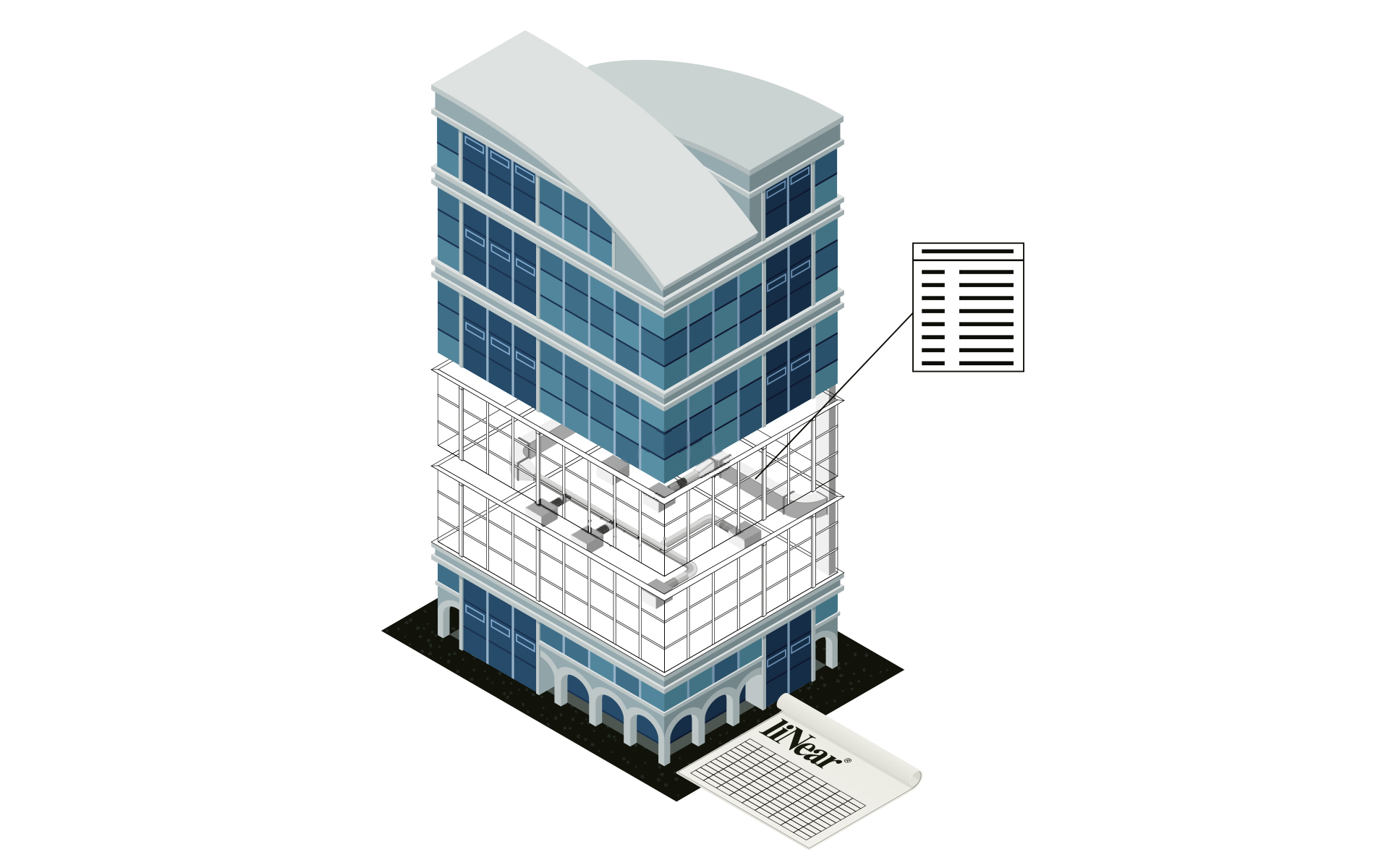

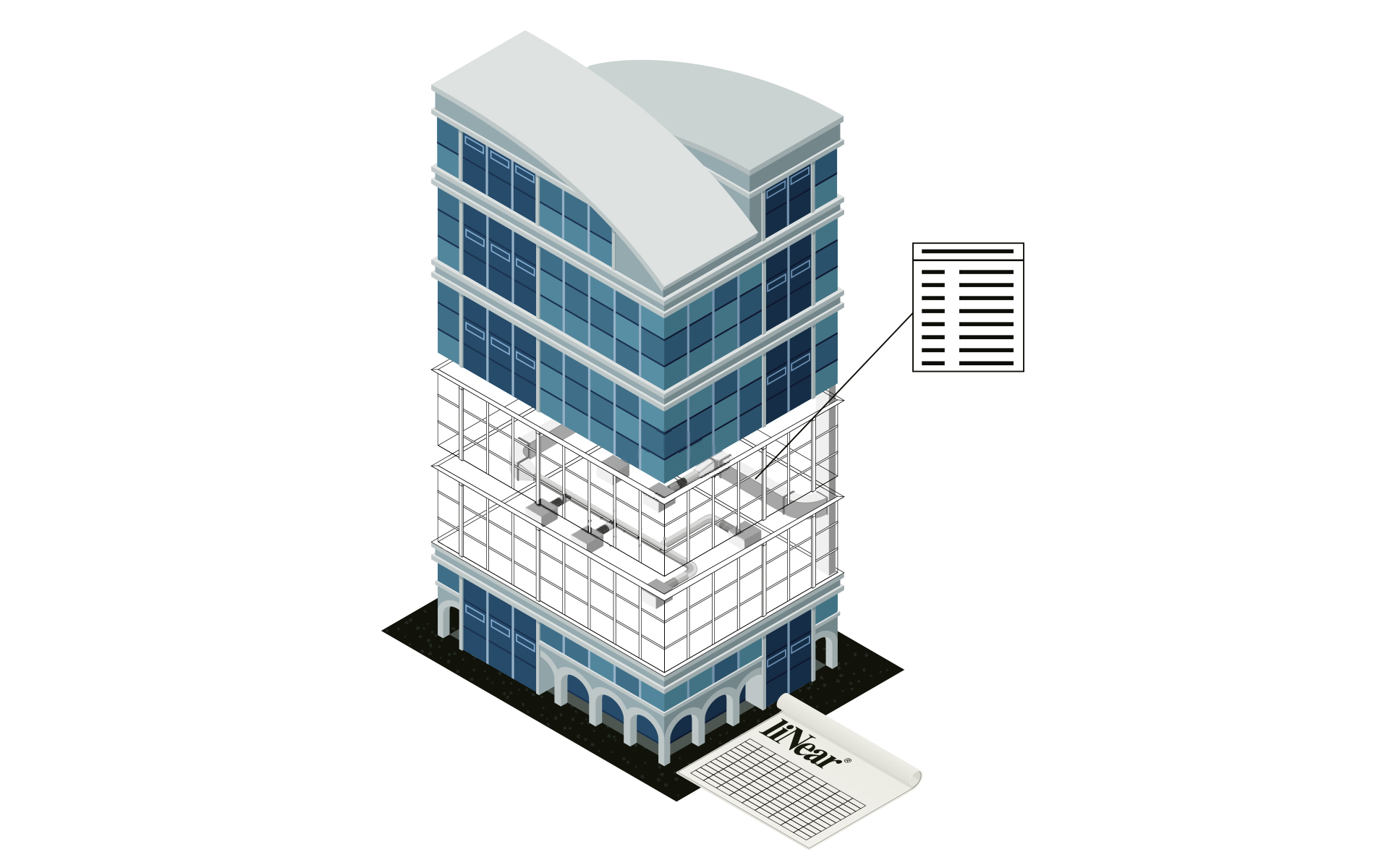

Detailed 3D Design (Ventilation) For example:

|

No | No | Yes |

|

Free Access to Online Tutorials

|

Yes | Yes | Yes |

Ventilation Solutions for AutoCAD

Editions

Videos

Description

LINEAR Workflow for ventilation design with Autodesk AutoCAD

Schematic design

Input: Supply requirements for the building

Output: Calculable scheme design

Work steps:

- Create storey table

- Manual scheme creation with toolbars and specific editing commands

Architecture as construction basis

Input: Architecture plan

Output: Model for further MEP design including levels and rooms

Work steps:

- Referencing DWGs, DXFs or PDFs from the architect

- Create storey table

- Create and enrich the architectural model for further construction

Determine volume flows, select outlets and configure the air handling unit

Input: Model for the MEP design including levels and rooms

Output: HVAC model with designed outlets and air handling unit

Work steps:

- Powerful building analysis as a basis for the cooling load calculation

- Automatic mapping of the building structure (building parts, storeys and rooms)

- Identification and collaborative correction of modeling errors in exchange with the architect

- U-value calculation and addition of any missing calculation parameters

- Dynamic cooling load calculation for the project, the storeys as well as all rooms

- Transfer of all relevant values into the model

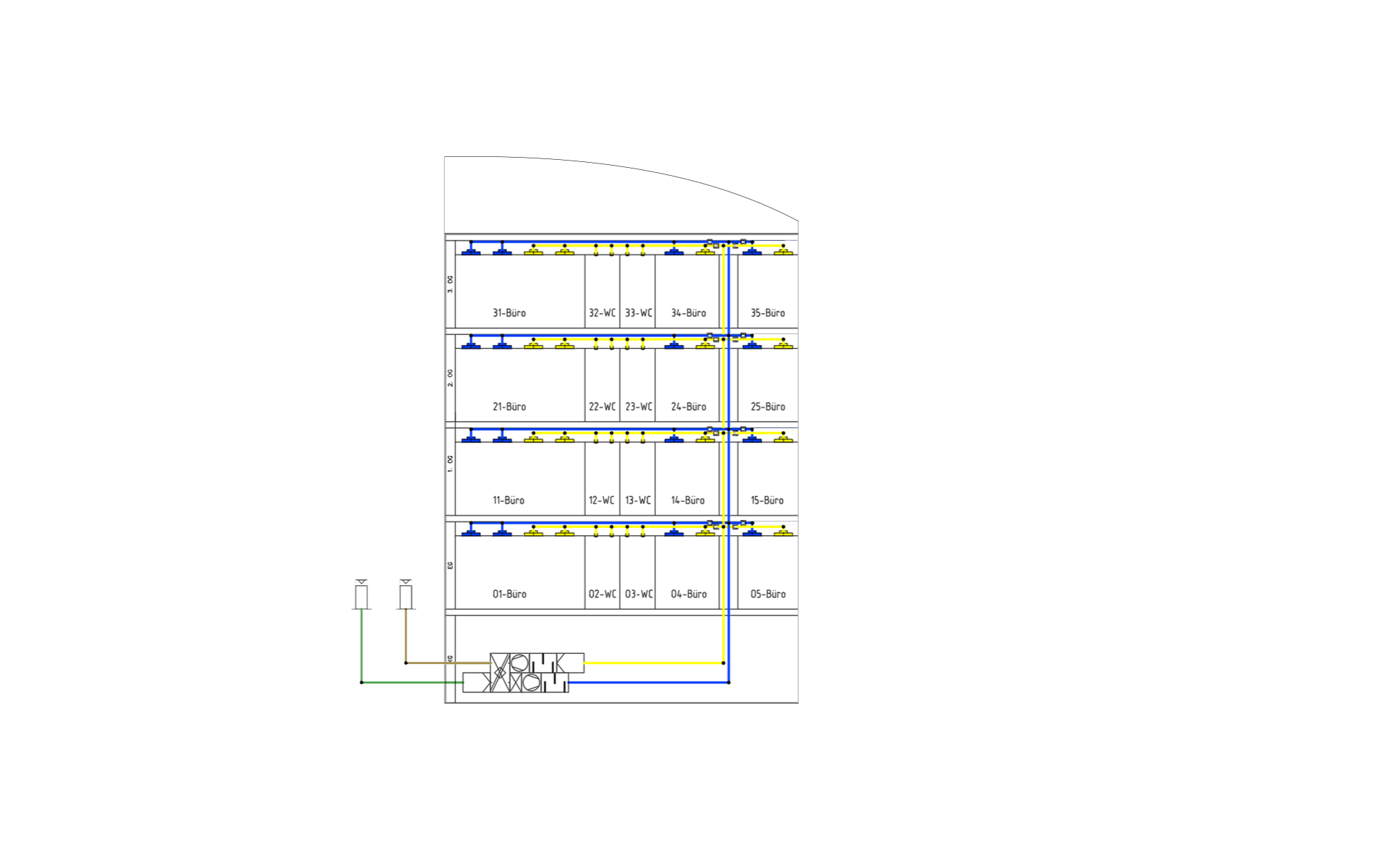

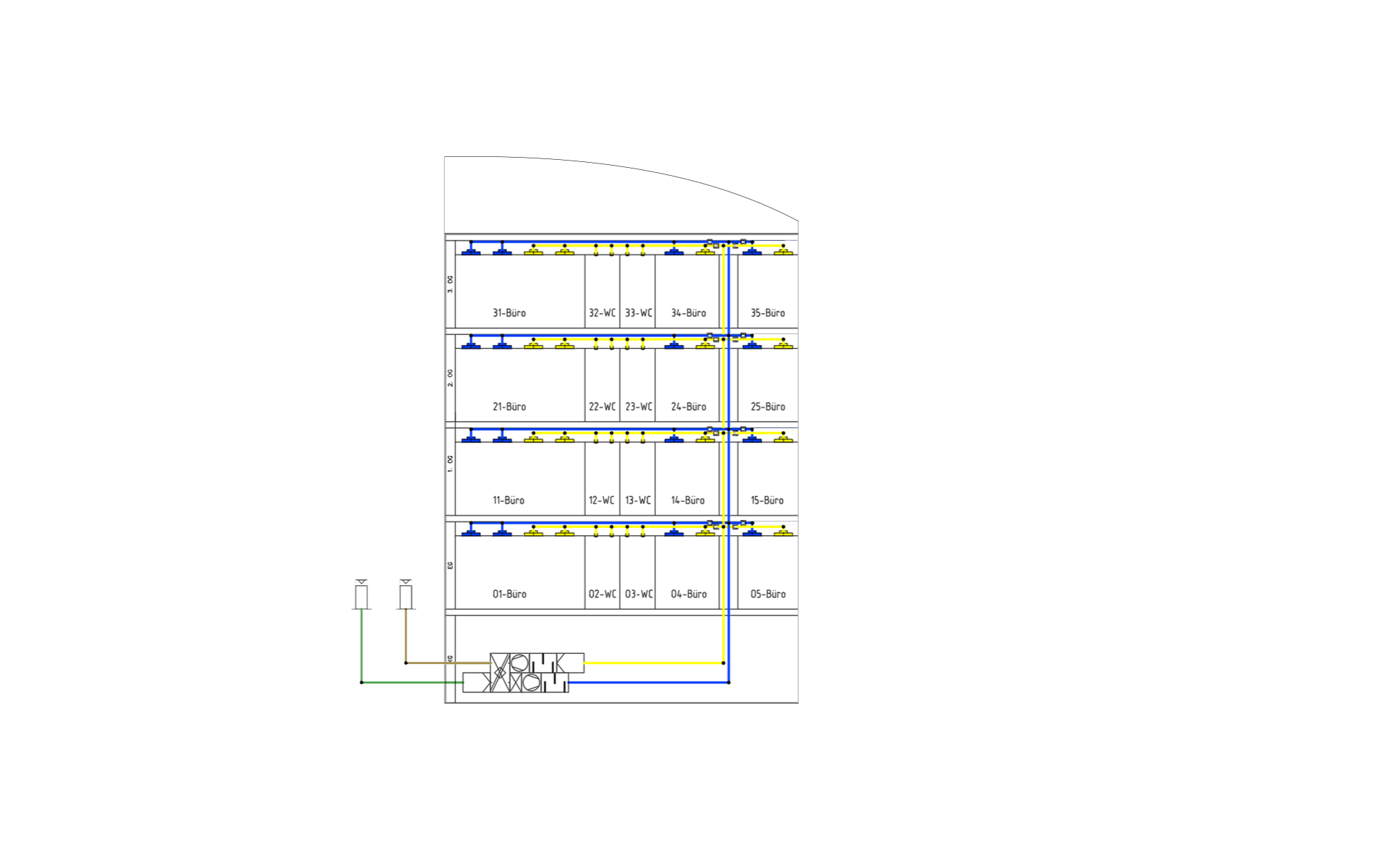

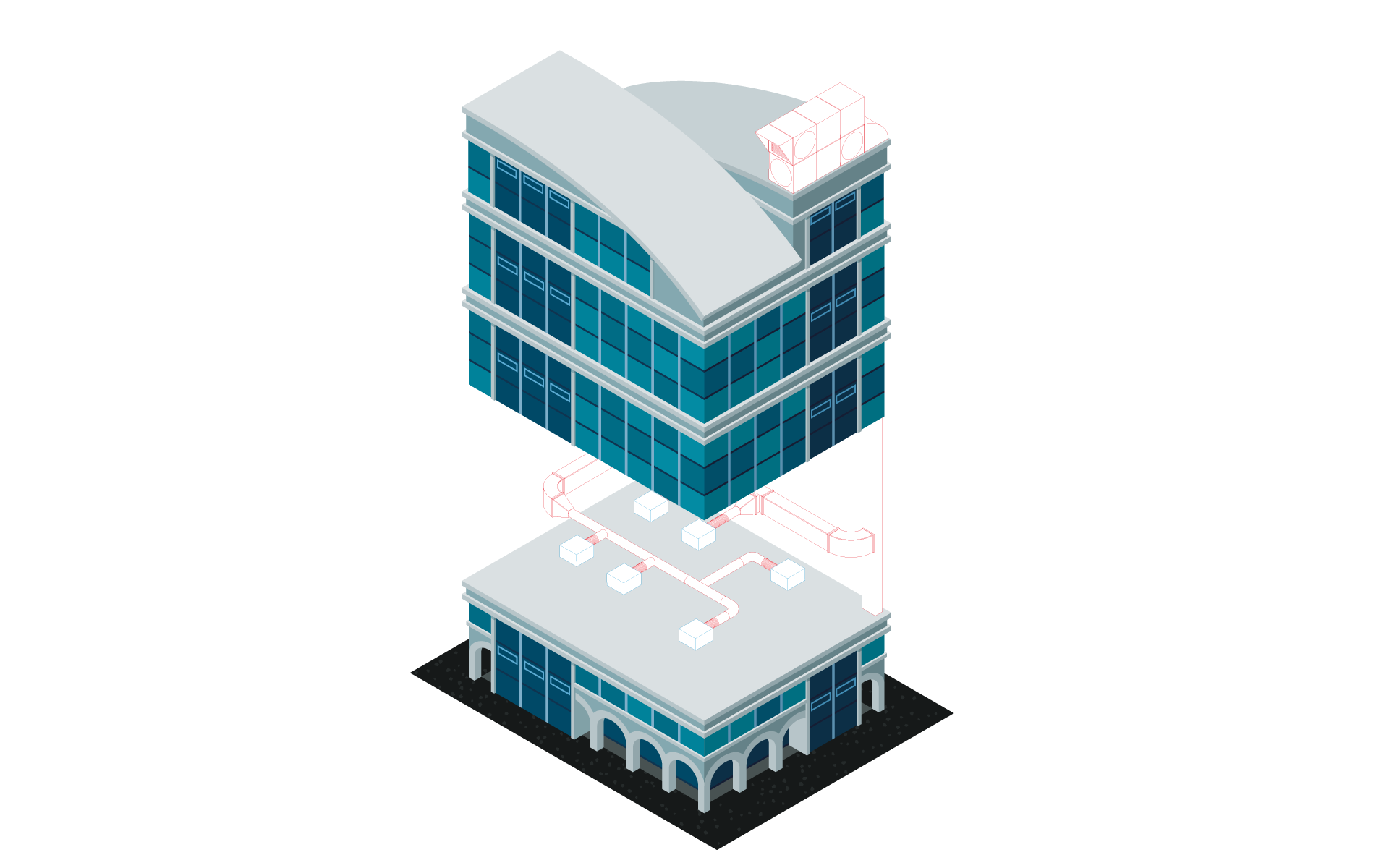

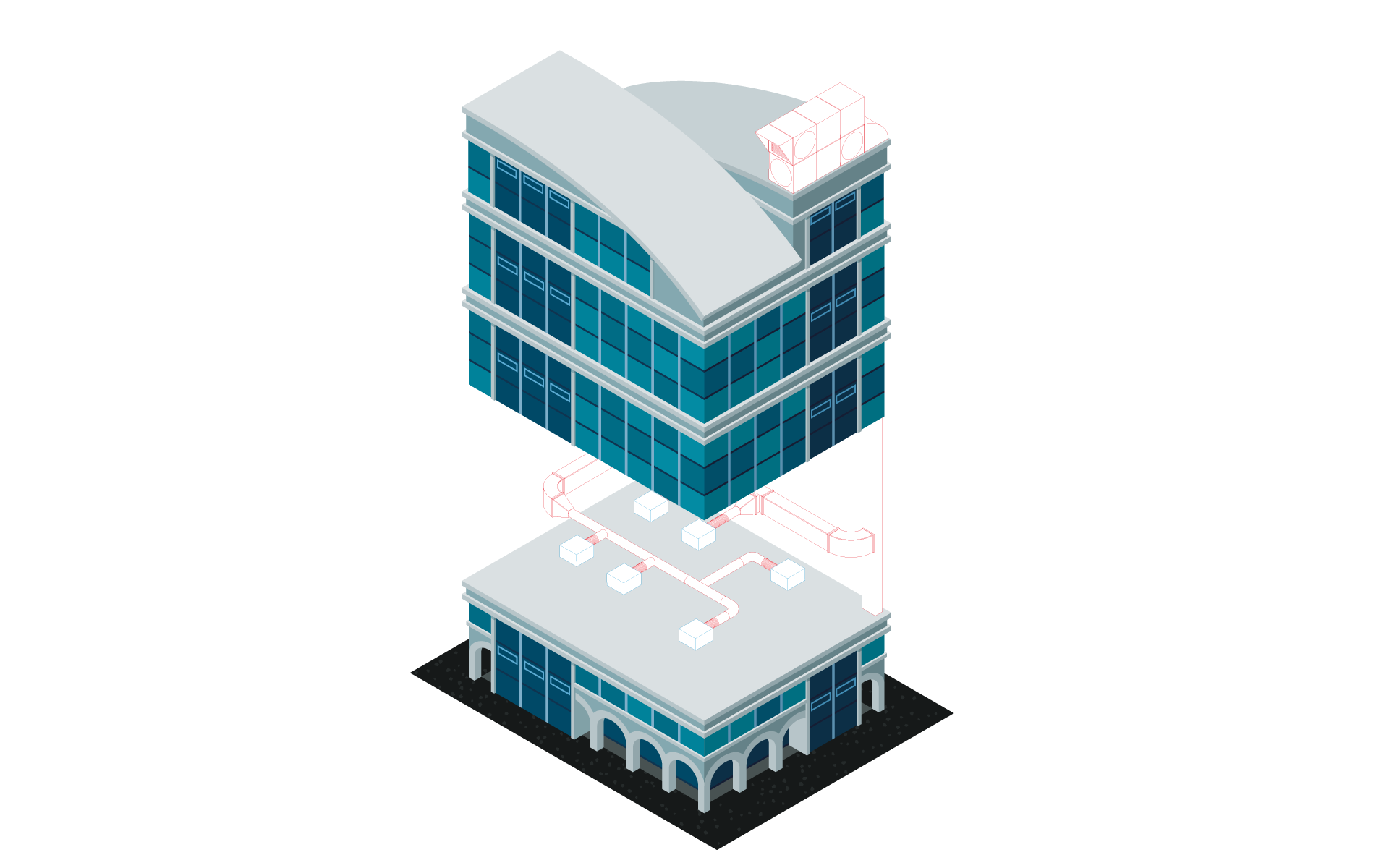

Create system in the isometry or floor plan

Input: HVAC model with placed outlets and air handling unit

Output:MEP Model with a calculable network (isometric or floor plan)

Work steps:

- 2D or isometric duct network design using time-saving construction commands

- Automatic connection of all outlets

- Insertion of built-in parts from neutral or manufacturer libraries (e.g., silencers or fire dampers)

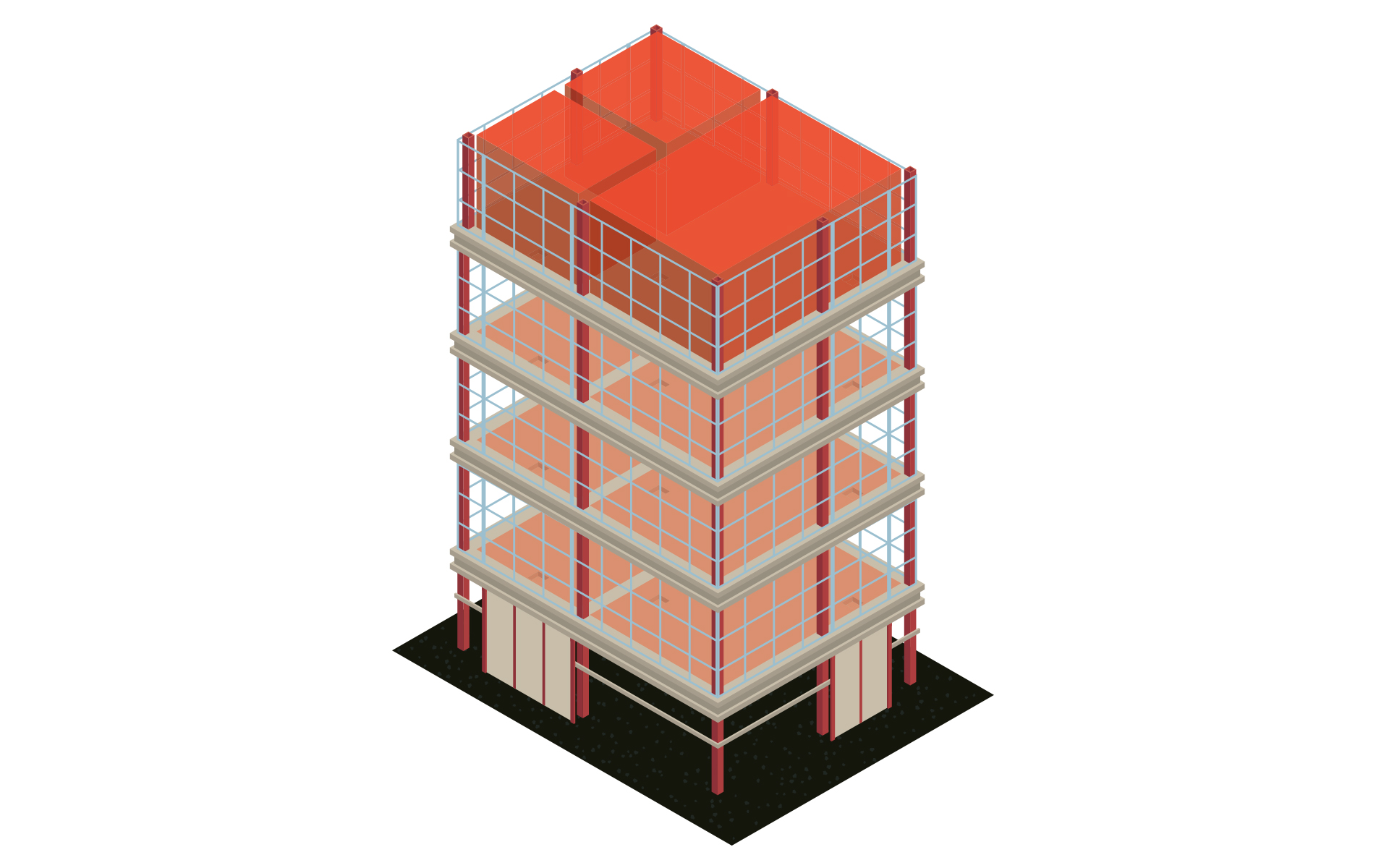

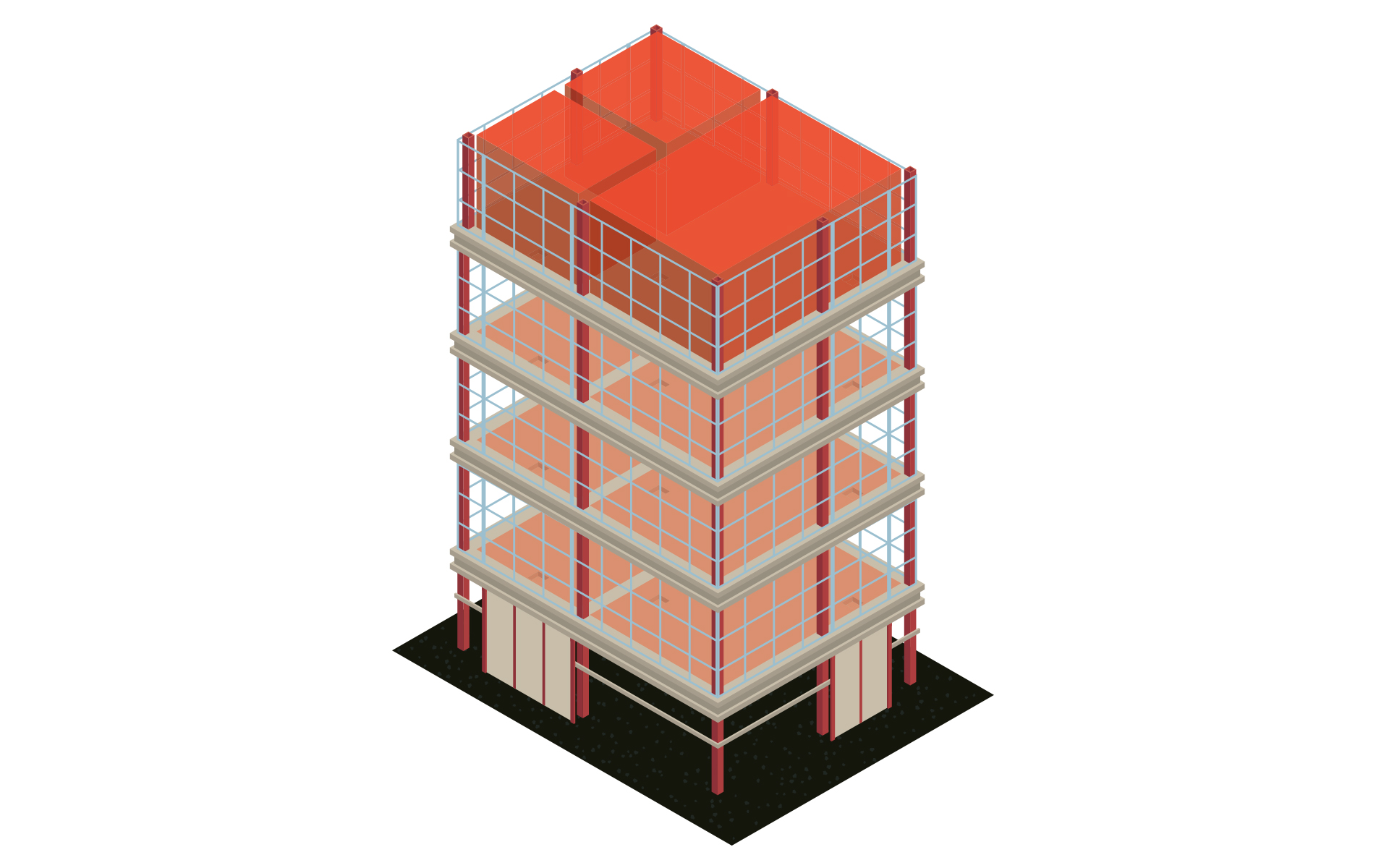

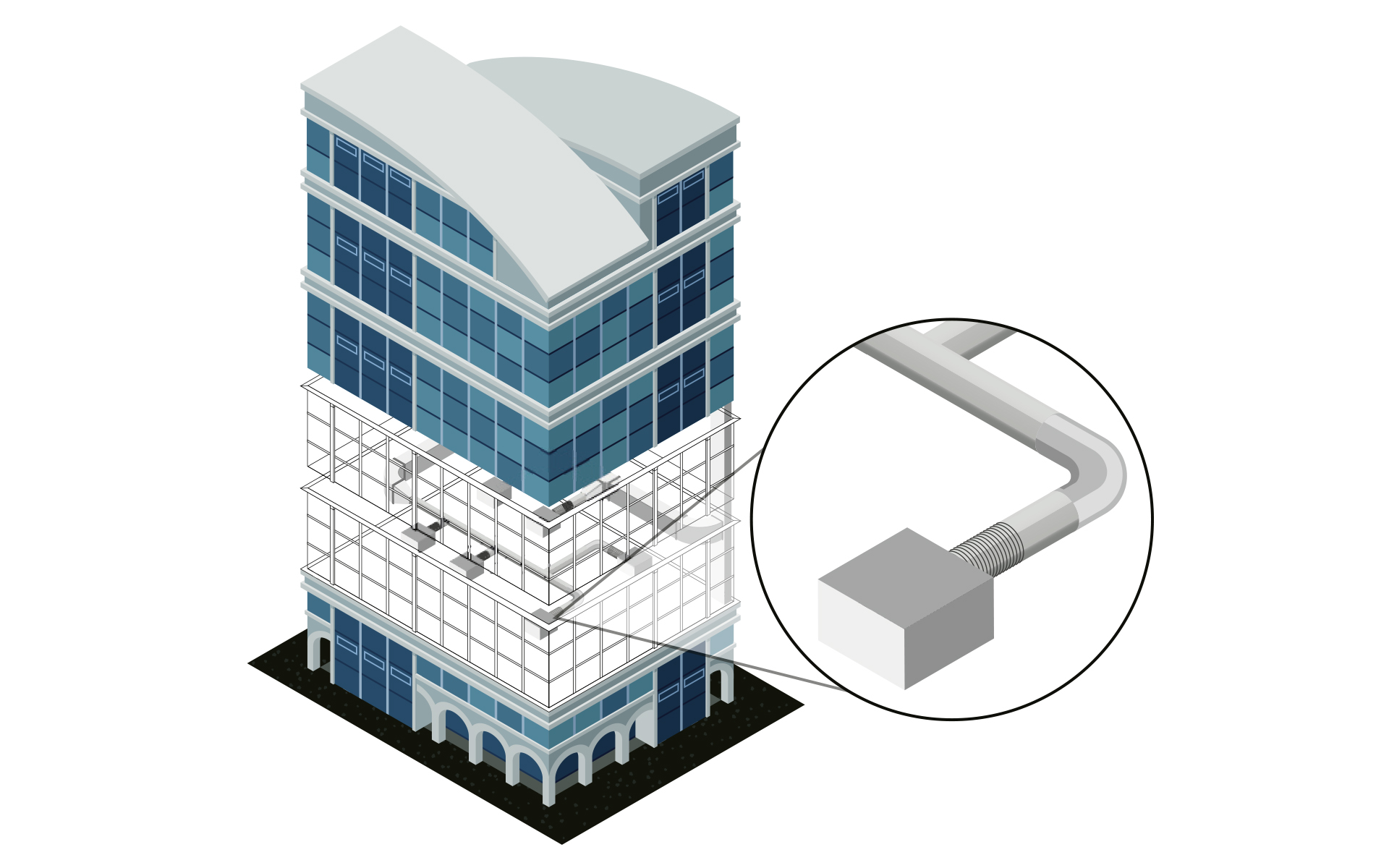

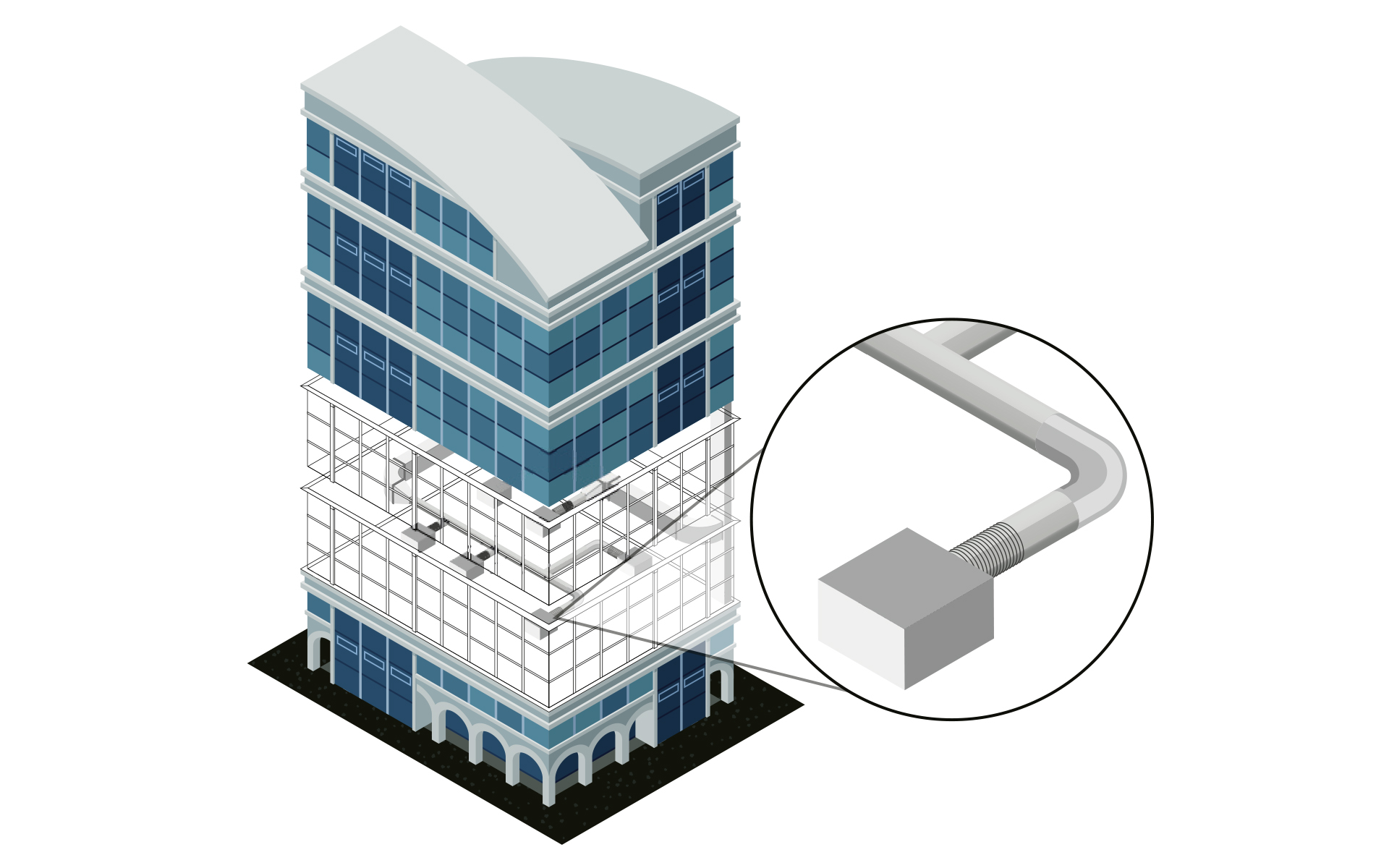

Create system in 3D

Input:HVAC model with placed outlets and air handling unit

Output: Detailed 3D model

Work steps:

- Automatic routing functions with preview of possible alternatives

- System design neutral or with the help of extensive manufacturer CAD libraries

- Subsequent placement of components with matching transitions and flanges

- Automatic bolting of the entire construction (bolts, nuts, washers) with complete transfer to the parts list

- Pre-define insulation materials and show/hide them with transfer to the parts list

- Real-time collision check

- Manually or automatically assigned item numbers

- Duct and insulation measurement, compilation of frame connectors with profiles and elbows, parts and position lists including all fittings

Air duct network calculation

Input: Schematic, 2D or 3D model

Output: HVAC model with designed outlets and air handling unitmodel with optimized ventilation system (schematic, 2D or 3D)

Work steps:

- Air duct network calculation (pressure loss calculation, flow-mechanical balancing, sound calculation).

- Support of several systems at the same time and many special constructions (e.g. cross-section splitting at grilles, several fans)

- Calculation of existing networks by fixing single or all dimensions

- Redimensioning of the air duct network based on the calculation

- Colored display of all results directly in the model (LINEAR Data Coloring)

- Transfer via e-klimaX directly to the air duct manufacturer

- Automatic 3D generation during system creation in 2D (step 4 - variant 1)

Labeling, output of model data and results

Input: Calculated and optimized ventilation network

Output: Final ventilation design including model for transfer to the coordination model and calculation results incl. material lists

Work steps:

- Saving of all inputs and calculation results in the model

- Publication of selectable values as component data

- Automatic labeling of the model

- Addition of own parameters and meta information

- Printout of the results in standardized forms

- Transfer of results and model in all relevant formats