| Features |

Starter

€ 59.00

/ month

billed annually |

Advanced

€ 149.00

/ month

billed annually |

Professional

€ 249.00

/ month

billed annually |

|---|---|---|---|

Features |

|||

|

MEP Model Creation (Potable and Waste Water) For example:

|

Yes | Yes | Yes |

|

Concept in Early Design Phases For example:

|

Yes | Yes | Yes |

|

Collaboration Tools For example:

|

Yes | Yes | Yes |

|

View Creator and View Control For example:

|

Yes | Yes | Yes |

|

Storey Table For example:

|

Yes | Yes | Yes |

|

Visibility Control For example:

|

Yes | Yes | Yes |

|

Task Management For example:

|

Yes | Yes | Yes |

|

Family and Library Manager For example:

|

Yes | Yes | Yes |

|

Industry Families via CAD Browser For example:

|

Yes | Yes | Yes |

|

Parameter Manager and Classification Tool For example:

|

Yes | Yes | Yes |

|

Collision Checker For example:

|

Yes | Yes | Yes |

|

Automatic Detection of the Potable Water Pipe Network For example:

|

No | Yes | Yes |

|

Potable Water Pipe Network Calculation with Redimensioning For example:

|

No | Yes | Yes |

|

Automatic Detection of the Waste Water Pipe Network For example:

|

No | No | Yes |

|

Waste Water Pipe Network Calculation with Redimensioning For example:

|

No | No | Yes |

|

Hydraulic Balancing of complex Systems For example:

|

No | Yes | Yes |

|

Bill of Quantities including Article Numbers For example:

|

No | Yes | Yes |

|

Free Access to Online Tutorials

|

Yes | Yes | Yes |

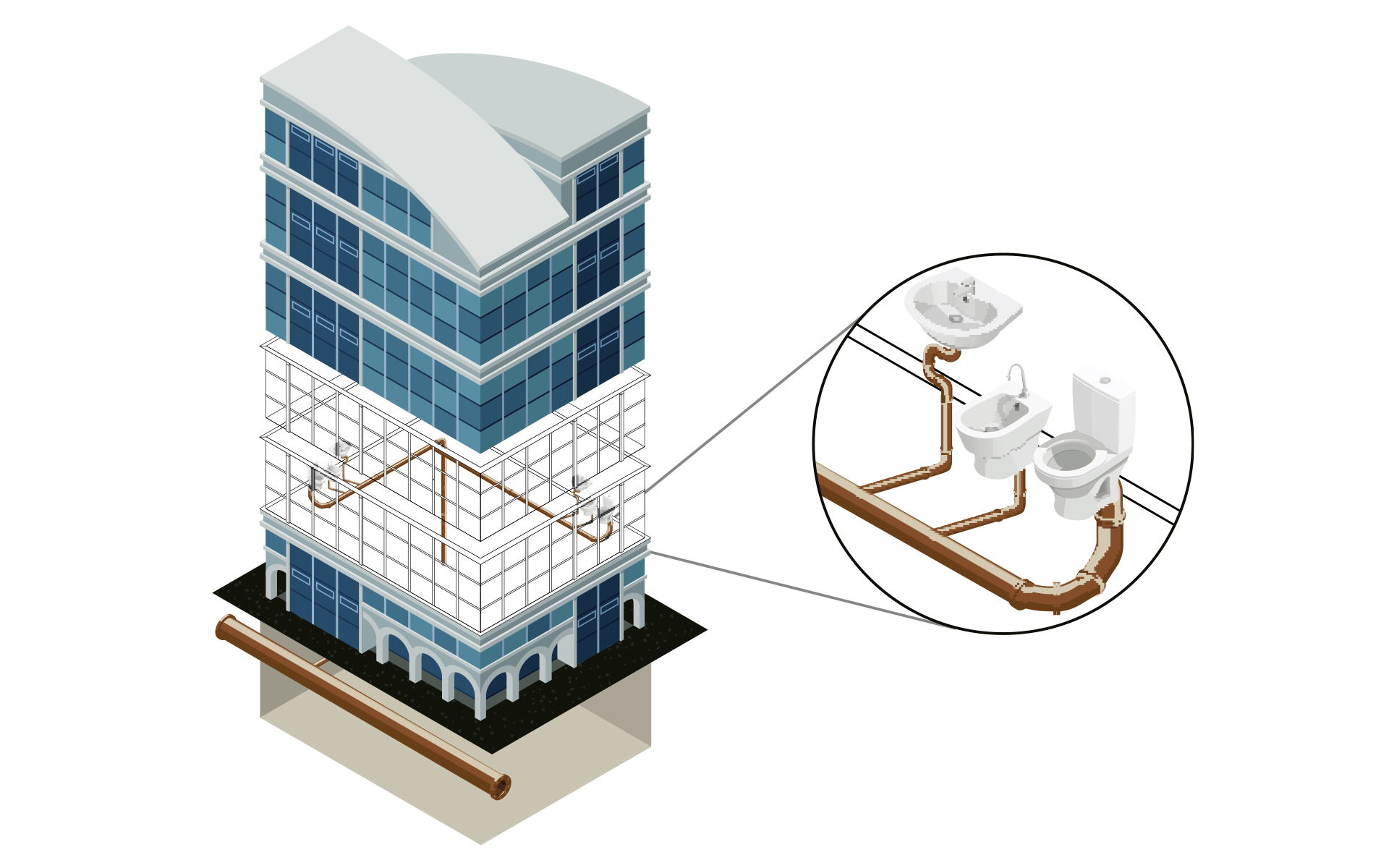

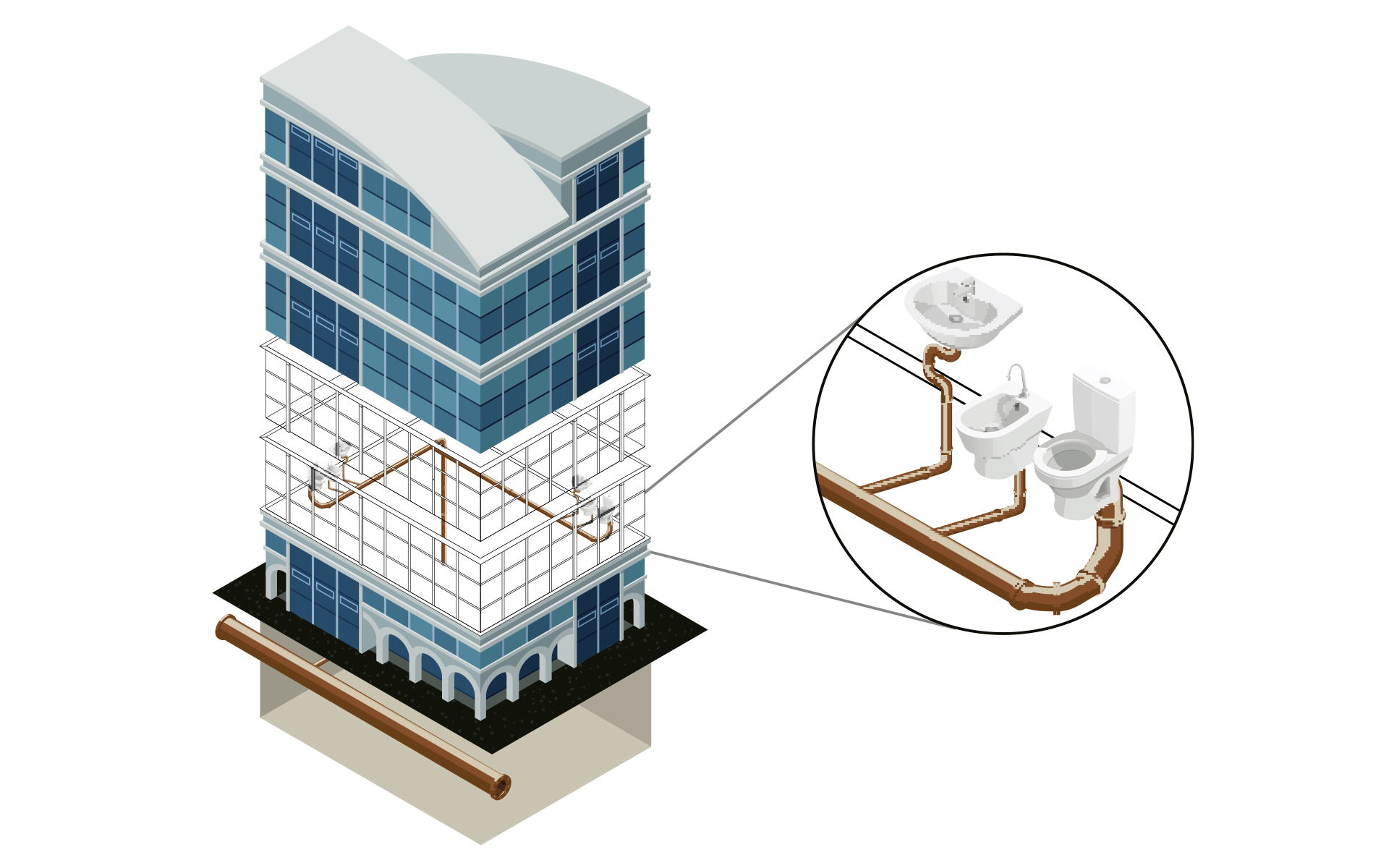

Water Solutions for Revit

Editions

Videos

Description

LINEAR Workflow for potable and waste water design with Autodesk Revit

Concept phase

Input: Concept structure of the architecture with rooms, floors and functional areas

Output: Located space requirements for technical rooms and pipeline corridors

Work steps:

- Workflow for a collaborative early design phase planning

- Creation of a concept design on the basis of the requirements planning

- Conceptual space design (Provision for spaces)

- Localization and pre-dimensioning of technical equipment rooms

- Localization and pre-dimensioning of the pipeline corridors

- Cross section editor for the pipeline corridor concept

- Generate pipe and duct elements from corridor concept

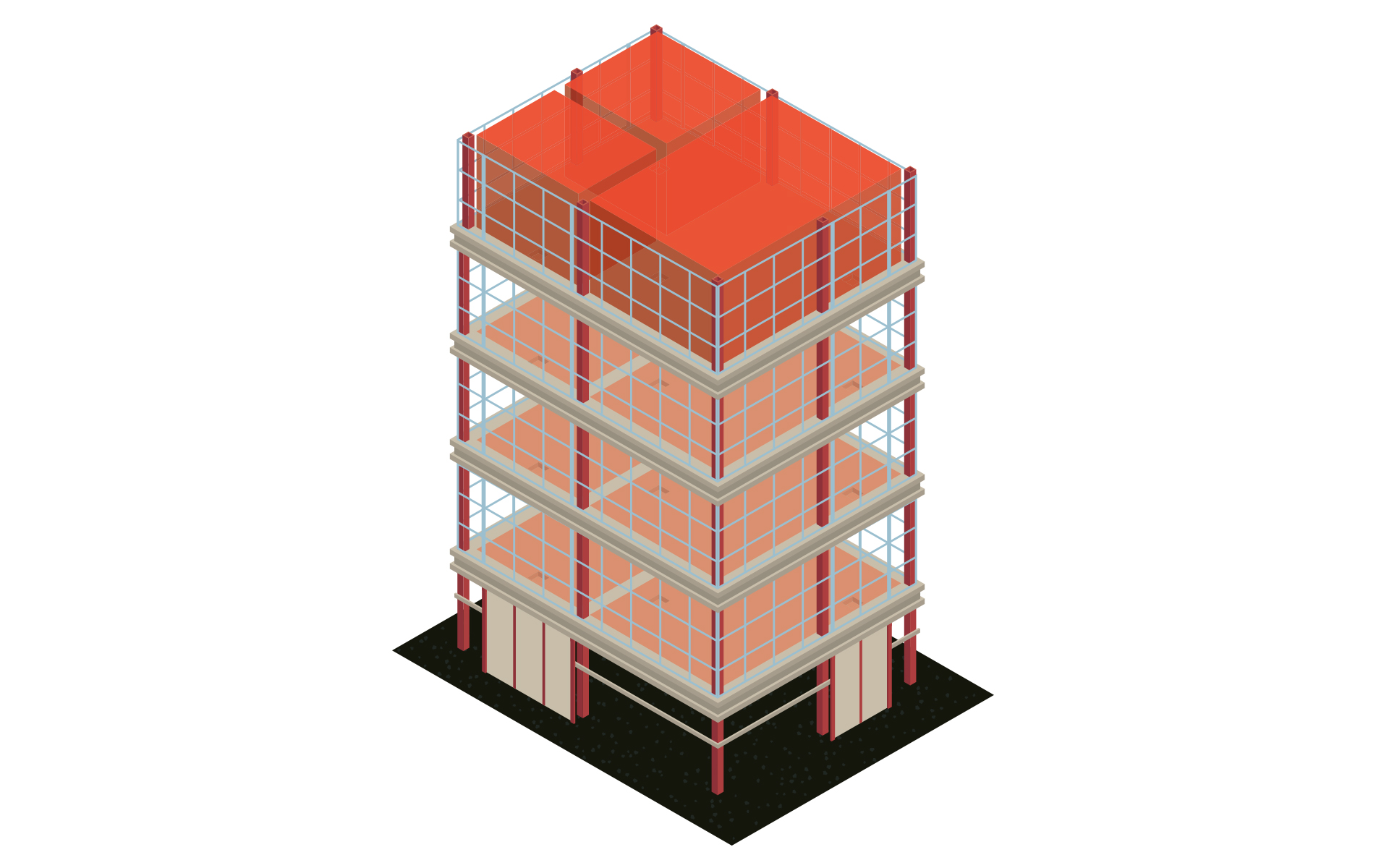

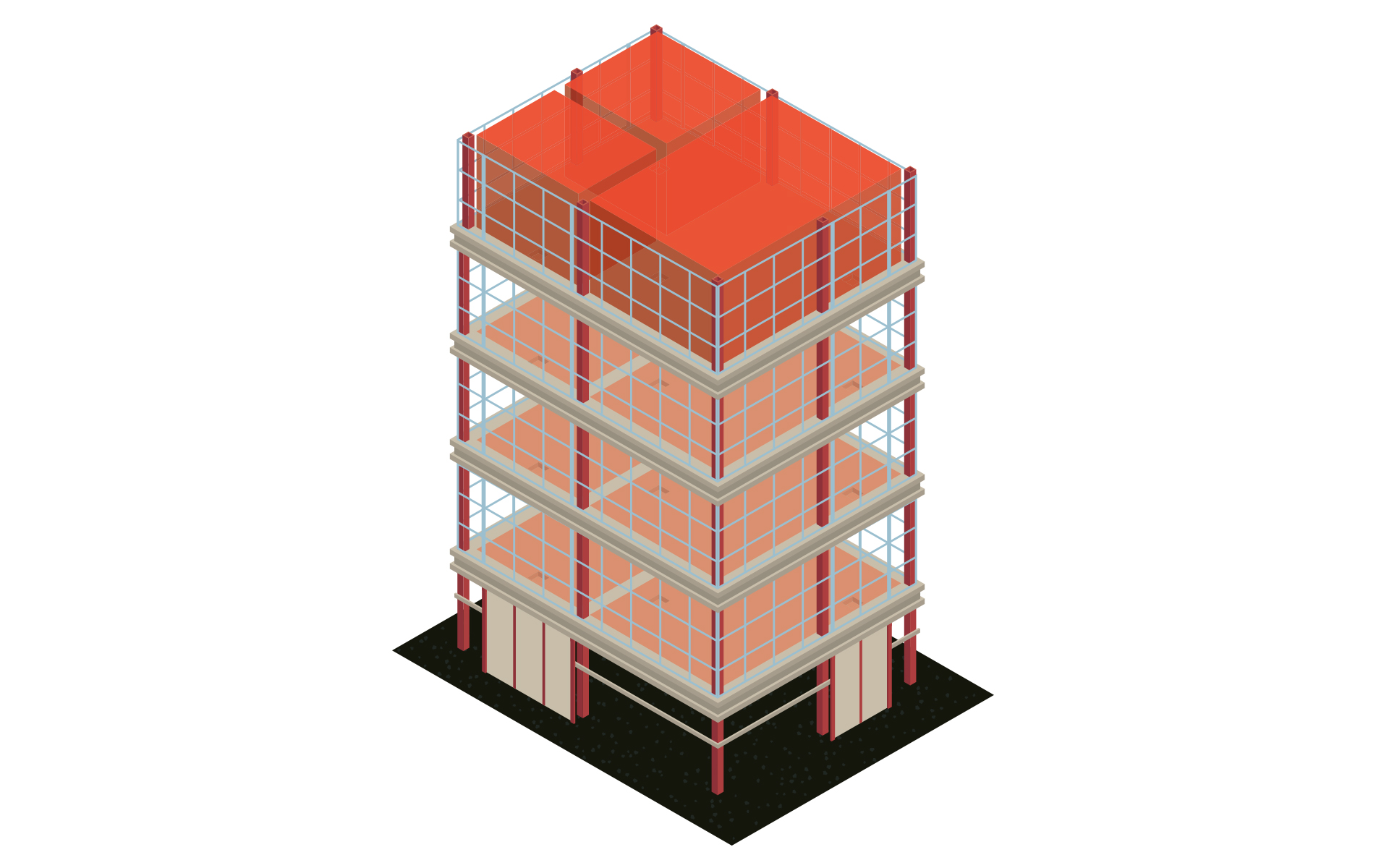

Building model as basis for design

Input: Architecture model or plan

Output: Model for further MEP design including levels, zones & MEP rooms

Work steps:

- Easy creation of the MEP model based on the architecture

- Enrichment of the model with relevant information

- Automatic creation of views and plans

- Parameter management for the assignment of parameters used in the project

- Optional for 2D templates: Simple rebuild of the building in 3D

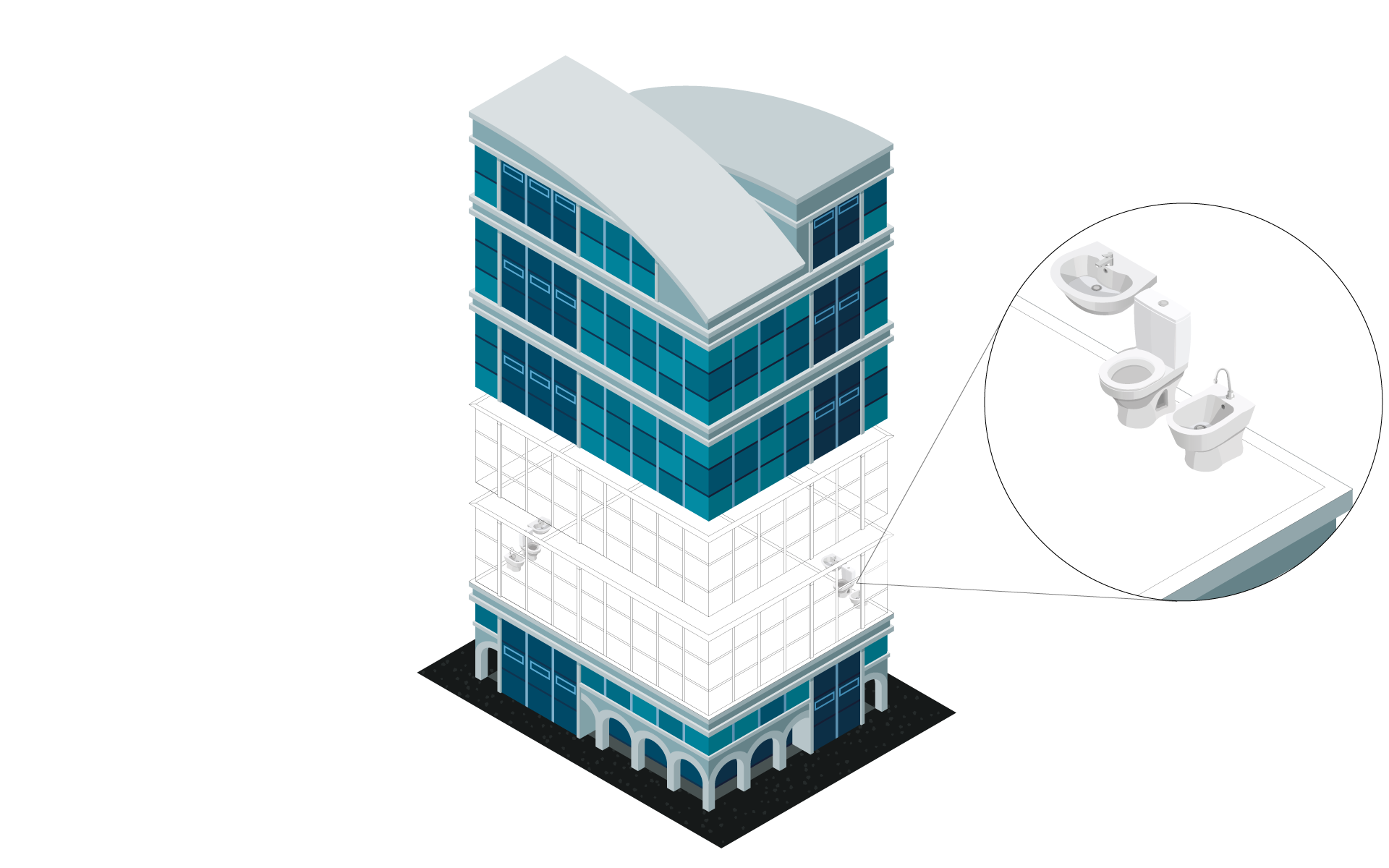

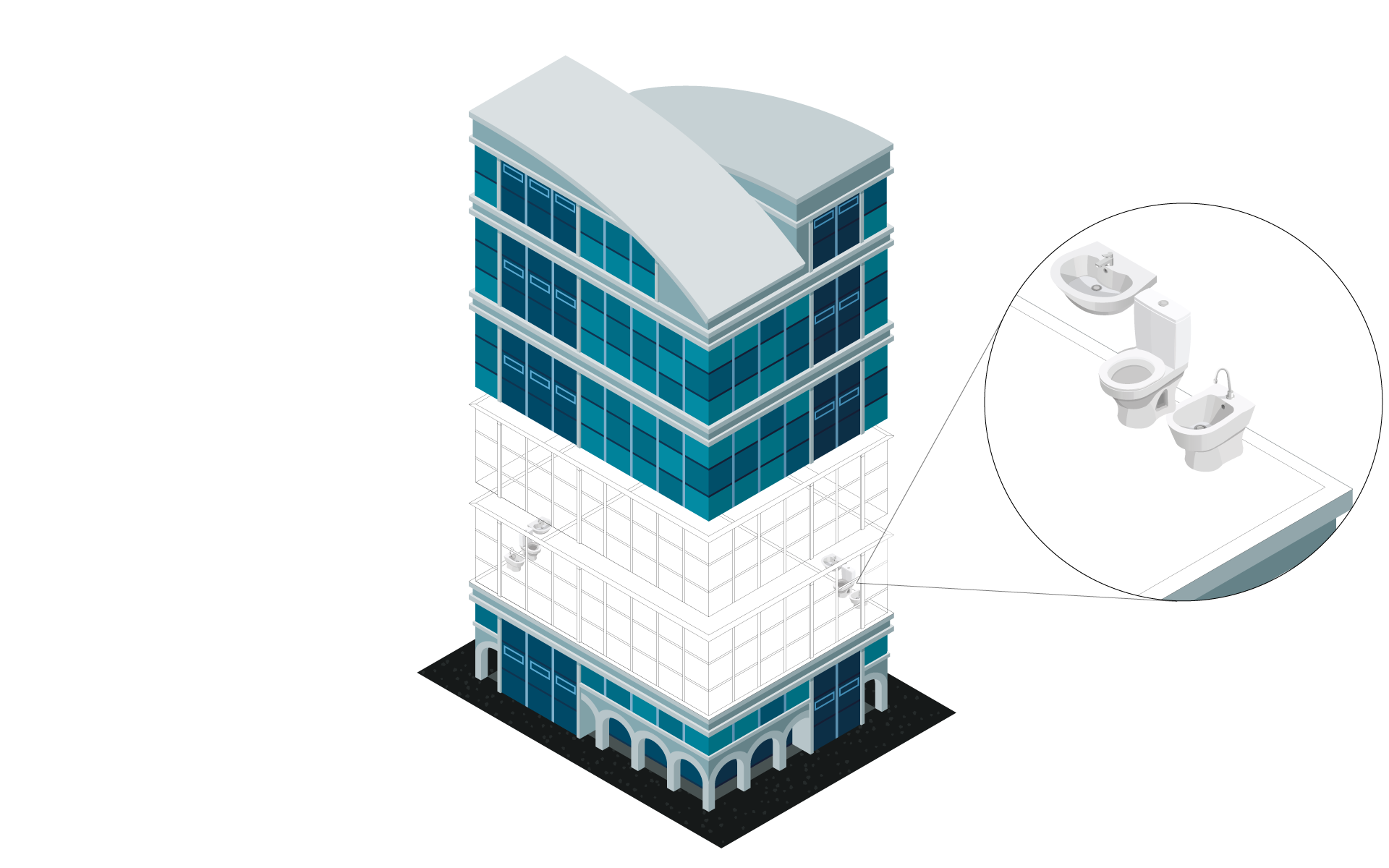

Positioning of sanitary objects

Input: Model for the MEP design including levels, zones & MEP rooms

Output: MEP model with placed sanitary objects

Work steps:

- Selection of sanitary objects as neutral components or from the extensive manufacturer CAD libraries

- Easy placement in the model through specific drawing commands

System creation and pipe network calculation

Input: MEP model with placed sanitary objects

Output: MEP model with optimized systems as well as the finished void planning

Work steps:

- Fast pipe network construction as a single pipe or as parallel pipes

- Automatic connection of all consumers

- Insertion of system components (e.g. house connections, filters, meters, fittings, separators, pressure boosting station)

- Specification of calculation-relevant specifications (e.g. assignment of pipe materials, settings of valves, specification of insulation, ambient temperatures or allocation of pipe materials)

- Simulation of ejection processes, check of comfort specifications and hygiene status

- Variant comparison by using verified manufacturer data sets (e.g. pipe systems)

- Automatic recognition of aeration ducts and types

- Calculation of (gravity) drainage systems for rain and waste water inside buildings

- Calculation of existing networks by fixing individual or all dimensions

- Redimensioning of the water pipe network on the basis of the calculation

- Colored display of all results directly in the model (LINEAR data coloring)

- Void planning including coordination via BCF and IFC

Labeling, output of model data and results

Input: MEP model with optimized systems as well as the finished void planning

Output: Final water design including model for transfer to the coordination model and calculated results incl. material lists

Work steps:

- Storage of all inputs and calculation results in the model

- Publication of selectable values as shared parameters

- Automatic labeling of the model

- Addition of own parameters and meta information

- Printout of the results in standardized forms

- Transfer of the results and the model in all relevant formats